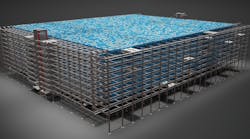

A scalable system, the tSort3D system can be deployed to multiply the destination density and volume of the sortation process for small and large applications; it is suited for fulfillment of items for customer e-commerce orders and other fulfillment flows such as store replenishment and reverse logistics. It features quick implementation, a modular design, and the ability to change alongside operational needs.

The tSort3D uses a tray as the carrier. The system is mated with the Tompkins Robotics tSort solution for item sortation loading and routing the items to tSort3D modules for order consolidation. Handling a wide range of products, the system allows six to eight times the sort destinations in the same space as other automated sortation solutions, provides for thousands of sort destinations, volumes up to 20,000 an hour, and facilitates a single, very large batch pick.

- Sorting speed: Up to 450 units per module per hour

- Max weight: 11 lb. (5 kg) load capacity

- Max product size: Up to 15 x 10 x 10 in. (38.1 x 25.4 x 25.4 cm)

- Sort destinations: Over 1,000 per system

- Module destinations: Up to 48 orders

- Destination size: Configurable

- Single module footprint: L 98 x W 35 x H 96 in. (L 248.9 x W 88.9 x H 243.8 cm)

- Induction mode: Automatic or manual