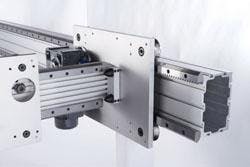

HEAVY DUTY SLIDE SYSTEM

HepcoMotion HDS2, now available from Bishop-Wisecarver, adds larger capacity bearings, assembled carriages, two new sizes of construction beam, and a host of improved features to the proven HDS product line. The advanced HDS2 system offers system capacities up to 68kN, and provides flexibility for many sizes and types of heavy duty components to be interchanged. Stainless steel or corrosion resistant component options further enable HDS2 to satisfy most high load application requirements.Retaining the best features of the previous version and incorporating them into a considerably expanded range, HDS2 is a technically superior product to the original HDS. An important aspect is the introduction of specific components that reduce the engineering time required by the customer to get the system up and running.Three new larger bearing sizes provide increased load capacity. These include a 150mm diameter vee bearing and a 144mm diameter taper roller bearing. Maximum single bearing capacity is now 50kN, a substantial increase from the previous 20kN. HDS2 double row bearings are exceptionally tolerant of debris. Low friction cap wipers expel dirt and debris, and provide continuous lubrication to provide a long service life. A removable cover allows easy system adjustment without disassembly.Slides and tracks are available in single piece construction up to 4 meters long, and are supplied in single or double edge format in V slides or flat tracks. The V slides have a simple alignment facility to achieve parallelism, while the flat tracks overcome the need to align two slides precisely parallel.Versatile construction beams with multiple slide and track mounting options add to the HDS2’s design flexibility, as does a larger aluminum beam which eliminates the need for a machined steel structure. A compact version of the beam is ideal where space is at a premium, or it can also be used to create a high capacity lifting Z axis. When the extra rigidity of a steel beam is required, all slides can be fitted and aligned using the keyway option with dowel pins. Customers may also mount directly to a HepcoMotion back plate using the alignment facility.Greater driving forces for heavier loads are achieved through a variety of spur or helical rack and pinion options. The package is complemented by rack driven carriages, automatic lubrication, and helical bevel gearboxes that can be driven by AC or servo motor.HDS2 is available in component form or as a ready mounted assembly including rack driven carriages. Customers can select either high precision ground slides when superior accuracy and highly smooth motion are required or low cost commercial slides for less demanding applications.