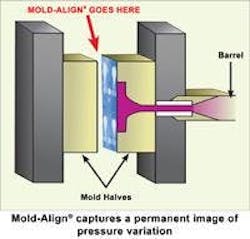

Mold-Align Helps Ensure Economical Precise Mating at the Parting Line

Mold-Align® is a new tool from Sensor Products Inc. that helps improve yields and reduce defects in the injection molding process. When placed between mold halves, it instantaneously changes color to reveal how pressure is being distributed between the A & B halves of the mold.

Traditional methods such as bluing agents do not work with the same precision or resolution as Mold-Align®. Mold-Align® provides data quickly with no messy cleanup and significant time savings.

Bluing agents, when applied to one half of the mold, will transfer to the other if there is any contact at the parting line, but will not distinguish between high and low pressures. Quality suffers and production time may be lost due to improper troubleshooting of flash, shorts, burns, etc.

With Mold Align® the process is quick and simple. It is placed between platens on the parting line which are then subjected to pressure upon clamp closing using minimal clamp tonnage. It is then removed and the image inspected for pressure distribution and void spots. Adjustments if needed are then be made to the platens to achieve alignment, open vents or repair mold damage. Properly mating parting lines and aligned platens reduce machine wear and improve quality. Mold-Align® may be archived and used as a control for comparative purposes.

Samples are available.

- reduce defects in the injection molding process

- provides data quickly

- process is quick and simple.