Why Automotive & Aerospace Manufacturers Are Looking to Wearables

Automotive and aerospace industries have complex manufacturing processes consisting of thousands of moving parts. These two industries, as a cross section of manufacturers, exemplify high value assembly lines where speed, exception handling, and quality control are critical to their business and competitive advantage.

The execution of these activities goes a long way towards driving the ultimate financial performance of the organization. It is a top priority for these leading manufacturers to identify tools and technologies that can improve employee performance in mission critical tasks.

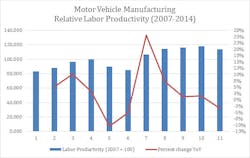

Productivity as a relation to human capital is in constant focus. A 2014 U.S. Bureau of Labor Statistics report noted an improvement in manufacturing productivity in 53% of manufacturing segments; automotive was not one of them despite the general advances in robotics.

One potential solution is that the human element of manufacturing can swing bigger gains if properly equipped with technology that modernizes the way people interact with manufacturing processes.

We hear from automotive and aerospace customers that a fully connected workforce – with ready access to instructions, expert assistance and communications while-doing their essential tasks – provides clear and immediate value to their organization.

Gartner Research has noted the advantages of a connected workforce as well and believes that manufacturing is leading all other industries with Internet of Things (IoT) connected devices.

This creates a unique challenge for automotive and aerospace manufacturers who have employees building their complex products. How are the employees performing manual tasks supposed to access that information if they are using their hands in the assembly process?

Why Wearable Devices Are Different from Other Mobile Devices

Wearable devices such as smart glasses and smart watches are an emerging breed of mobile technology that has the potential to contribute to greater manufacturing outputs by giving the workforce a direct interface to the smart systems and automation investments around them.

Smart glasses are considered the most powerful of the wearable devices, and enable a manufacturing workforce to receive information and alerts from enterprise networks while remaining hands-on with their work.

Imagine the increased efficiency on an automotive assembly line if you could visualize the custom ordered trim package on the car coming down the line without having to fumble around for a manifest list.

The information is in your line of sight when you need it.

Smart glasses allow employees to connect to the information generated in an IoT environment while remaining hands-on in the manufacturing process. Smart glasses also allow employees to become digital contributors or nodes, as Gartner puts it, in the IoT network.

Employees with smart glasses can do more than passively receive information from enterprise networks; they can contribute by documenting issues and receiving real-time remote advice on how to address the issues. People doing complex or custom configuration or exception tasks can call an expert to get guided help, speeding up these activities.

Real-time, in the moment, uses are not the only way organizations are thinking of using these new tools. Any set of glasses on the right user can make videos of best practices and exception handling for training and benefit of all employees. Being able to capture images or videos of the actual work as its being done has also been shown to improve compliance. Smart glasses allow information sharing and connect the manufacturing workforce in ways previously not possible with a tablet, smart phone or laptop.

In addition to having in-view guidance that can drive down production error rates and the corresponding need for re-work, for large organizations such as automotive and aerospace manufactures, shaving just a few seconds off each task in the assembly process can result in big time savings.

For example, if an employee equipped with smart glasses can do a task 12 seconds faster, that may not seem like much at first glance. But, when that task is performed 100 times a day across 1,000 workers, an organization can save 86,000 hours annually in its manufacturing process.

Ultimately, automotive and aerospace manufacturers are seeing that things are done faster, done right and done once with a connected workforce leveraging smart glasses.

Smart glasses can enable workers to access instructions, tutorials, and key process data in real time on the factory floor via a heads up display.

Getting Started: Start Small

The desire for continuous improvement is a common factor that we have seen among all of our smart glasses customers in manufacturing. These businesses recognized that there is a better way to execute complex assembly jobs. They also recognized that there are many areas in their factories where people are doing many types of hands-on work. Finding a place to start with smart glasses can be overwhelming.

There are different production lines, different products, different steps in the process and each has slightly different needs. Should a first deployment of smart glasses be in materials handling and logistics? Should manufacturers examine applications in asset maintenance and repair? Could these devices benefit equipment and plant monitoring?

Automotive and aerospace manufacturers typically see the need for a solution in all of these areas.

The best way to begin is to start focused. Identify areas where there are specific problems that need real-time solutions. Don’t try to boil the ocean, but instead look for a use case that can be easily replicated and expanded – we have found that having a few dozen people involved in the initial process gives a company enough of a sample size to assess effectiveness and create a supportive study.

Pick an area where smart glasses aren’t too “whacky” of an idea. As mentioned previously, smart glasses have shown themselves to be the most powerful and flexible of the wearable devices but they are also the best suited for core production tasks. Since many of these employees are already wearing safety glasses, introducing smart glasses to their uniform is not a cumbersome addition. Think of them as smart safety glasses.

Smart glasses are also only as capable as the software powering the user experience and coordinating the business logic of the manufacturer. Companies can grow their own solution or seek a professional grade platform to give them access to industry ready features or broader device support.

Because APX Labs’ software platform works across all enterprise wearables, we are able to help organizations choose the right wearable device that best suits their specific manufacturing needs and environment.

Some smart glasses provide a more immersive experience. Some are more rugged. There are many considerations manufacturers should take into account when determining the right wearable device for the job. For example, do your employees wear thick gloves that make touch pad navigation impractical? Would voice commands provide a better user interface, or do your employees work in a noisy environment that would drown out voice commands? Perhaps gesture control is a feature your smart glasses need for optimal operation in your manufacturing environment.

Final Thoughts

Manufacturers that identify problems that need solving in real-time have the potential to see major productivity and compliance gains from an effective smart glasses.

This is especially true in the automotive and aerospace industries, where there are more than one million manufacturing and production workers in the United States alone.

We strongly believe that anyone who builds, moves, fixes or monitors assets for their job can benefit from wearables in the workforce’s toolbox.

We are encouraged by the growing investments in IoT as a sign that manufactures will recognize that the information produced by this network becomes its most powerful when it is put in the hands of their workers -- or more accurately, in the workers’ line of sight.