On the third Monday of every month, we recap three stories from the 3D printing industry to show you this technology has the ability to alter not only how things are made, but how we live. This month we wrap up some of our favorites from the 2016 Consumer Electronics Show.

Jr. Print

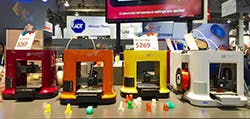

Technology doesn’t become ubiquitous until it becomes affordable, and XYZprinting introduced a device at this year’s show that could very well propel 3D printing into the mainstream stratosphere. The da Vinci mini, not to be confused with the automated surgery system, is touted as the lowest-priced of its kind to come completely assembled.

The Wi-Fi-capable printer measures 15.7 x 13.2 x 14.3 in. and has the same 5.9 x 5.9 x 5.9-in. build space as last year’s da Vinci Jr. It's estimated to cost $269 and should arrive in Q3. That will seem like an eternity to 3D-printing fanatics who can't wait to bring home the “Reviewed.com/USA Today CES Editors’ Choice Award” winner.

"XYZprinting is dedicated to bringing affordable and approachable 3D printing technology to the masses, and this award gives us validation that we are doing just that," CEO Simon Shen said.

Cosplay Just Got Real

We have to give major props to sci-fi costume maker Anovos, who displayed a full-scale “Star Wars: The Force Awakens” stormtrooper entirely manufactured by its 3D Systems industrial 3D printer.

The company worked closely with the movie’s production team and had the actual digital files to make the scale model—made form 40 different pieces—as detailed as possible.

A 3D-printed Captain Phasma was also supposed to be at the show, but like in the movie, was nowhere to be found when it counts.

Light Speed Prototyping

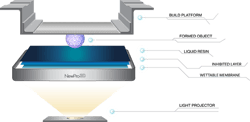

After seeing NewPro3D’s Intelligent Liquid Interface (ILI) process, you get the feeling that a superlative needs to precede “rapid prototyping.” The company explains ILI as integrating “a clear wettable membrane between the photo-curing resin and the light source.”

This allows the Candian-based manufacturer to create an object 51-mm in diameter in only 4.5 min. It takes a polyjet printer 180 min. to accomplish the same task. According to 3Dprint.com, NewPro3D is also developing a 3D printer to make 25-ft. turbine blades in 16 hours and a faster way to 3D print metal.