What Are They Using? Idnet Enhances Ergonomics With Southco, FLIR Helps Monitor Paper Production, Oritek Turns to Ceva's AI Vision for Its EV Chipsets, and More

Highlights:

- Industrial Video Systems chooses FLIR for its infrared thermal cameras to accurately measure moisture and temperature in its paper-making process.

- Oritek Semiconductor chooses Ceva's SensPro Vision AI DSP software in its Longquan 560 series of semiconductors to gain high-performance, energy-efficient processing for ADAS.

- Idnet chose Southco's AV Monitor Mounts to enhance the ergonomics of its workstations.

- Producers Peanut chose WECO's PeanutTek active moisture monitoring system to improve its peanut drying process, even remotely.

Have you ever been curious what your main competitor or even just other companies similar to you are using in their facilities? Maybe you saw a machine or piece of equipment and wanted to know where it was from and if they like it.

In this recurring news round-up, we'll be compiling all the news about who bought what, who delivered what to who, and so on so you can see how other companies are operating and the tools they're using.

Industrial Video Systems Chooses FLIR for its Patented, Award-Winning Thermal Imaging Solution

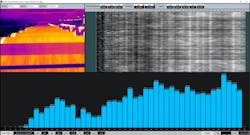

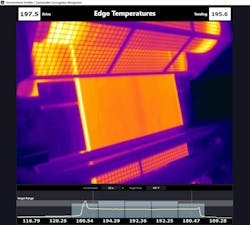

Industrial Video Solutions, Inc. (IVS), a US-based specialist in automation for the papermaking industry, has turned to using FLIR infrared (IR) thermal cameras to obtain valuable data from paper machines as part of a patented system that boosts machine control and efficiency.

IVS was having an issue with accurately measuring moisture and temperature in its paper-making process. Even though it had several cameras set around its facility, some aspects were still invisible to operators. Given the steamy operating environment, camera limitations, and a lack of tools that convert camera images into actionable data, they needed a solution.

IVS created a patented solution named ThermoVision which integrates FLIR IR cameras to see real-time moisture profiles in any paper machine location, mapping them to a multifunctional thermal profiler. The system can provide real-time, full-width, cross-direction moisture, and temperature profiles, as well as real-time machine direction profile variations. Using a FLIR IR camera to capture an image of a pulper vortex, for example, allows users to see through the steam and visualize the vortex in full detail, including the position of the chain and vortex edges.

While it only requires a single FLIR IR camera to execute all ThermoVision analyses, multicamera systems are more effective for troubleshooting, optimization, and improvement. It's even possible to feed data from these cameras to an AI module which then learns the relationship between the forces exerted on the paper, paper vulnerabilities, and process upsets to predict potential failures.

"We came across the potential for this technology by chance. We had already patented our ProcessVision technology, which extracts pixels from an image to effectively turn an area-scan camera into a linear camera when a potential application provided us with a new idea," says Slawek Frackowiak, President and CEO of IVS.

"I discovered that while a few competitors had started using IR cameras for displaying video, they were not doing anything with that output. In a papermaking machine, temperature is inversely proportional to moisture, so we set about developing a new system—ThermoVision—which combines the concept of our existing ProcessVision with FLIR thermal cameras."

Depending on the application, IVS uses either FLIR A50/A500 or A70/A700 FLIR IR thermal cameras.

Due to their higher resolution, the FLIR A70/A700 models tend to be used for papermaking machinery applications but ThermoVision can also benefit machines that produce corrugated paper for packaging. IVS uses FLIR A50/A500 series cameras for corrugators since it doesn't require the same level of resolution, minimizing costs for customers.

Oritek Semiconductor Chooses Ceva's Multitasking AI Vision Software for Its EV Chipsets

Oritek Semiconductor has licensed Ceva's SensPro Vision AI DSP for its Longquan 560 series of Advanced Driver Assistance Systems (ADAS) chipsets for electric vehicles (EV) needs. The chipsets can be used for AI-based headlights, camera monitoring systems, zone control units, and integrated central computing units for driving and parking.

Ceva's Vision AI DSP is a high-performance, low-power processor for complex sensor processing and AI workloads. Combining the two accelerates time-to-market for automakers, reducing their development costs and making it easy to integrate advanced features.

SensPro is a scalable vision AI DSP for multitasking sensing and AI workloads of multiple sensors including camera, radar, LiDAR, time-of-flight, microphones, and inertial measurement units. The SensPro family handles multiple sensor processing for contextually-aware devices and can be used in modern intelligent systems in automotive (inc. ISO26262 functional safety compliance), robotics, surveillance, AR/VR, voice assistants, wearables, mobile and smart home devices.

The SensPro maximizes performance-per-watt for multi-sensor processing use cases by utilizing a combination of high performance single and half precision floating point math, point cloud creation and Deep Neural Network processing, along with parallel processing capacity for voice, imaging, and Simultaneous Localization and Mapping (SLAM). For more information, visit https://www.ceva-ip.com/product/ceva-senspro/.

"Ceva's SensPro Vision AI DSP, embedded in our Longquan 560 series, provides the high-performance, energy-efficient processing essential for ADAS innovation," said Mr. Gao Feng, CEO of Oritek. "Our collaboration will empower automakers to meet the demands of a fast-evolving automotive market, delivering smarter, safer, and more reliable solutions."

"Oritek's selection of our SensPro processor reinforces the market-leading performance we enable for advanced sensing and processing capabilities required by today's automotive leaders," said Ran Snir, vice president and general manager of the vision business unit at Ceva. "With SensPro's unique capability to seamlessly handle the most intensive real-time workloads associated with critical ADAS applications, we are excited to collaborate on delivering cutting-edge solutions for the rapidly expanding EV market."

Idnet Enhances Workstations With Southco Monitor Mounts

Idnet, a company that helps warehouses and stores modernize operations for better efficiency and adaptability through tailored IT tools and ergonomic solutions, needed some help with its latest high-tech mobile workstation.

The mobile workstation with integrated IT solutions for e-commerce and warehouses expedites workflows and increases productivity by implementing an easy-to-use digital interface that connects users to goods and materials handling, specifically the picking process.

The goal was to find a solution that promised high cycle-life position control, including eliminating time spent re-adjusting the screen due to loose hinges or stiff structural properties. It also needed to withstand daily use with minimal upkeep.

Idnet decided on Southco's AV Monitor Mounts, which are height-adjustable arms that enable ergonomic positioning by adjusting height and tilt angles. Operators can grab and move the screen without effort and the mounts securely hold the touchscreen in any position and resist unwanted movement when used.

Southco's AV-D32 height-adjusting arms optimized the digital interface monitor, allowing movement across three different axes.

The AV-D32-30V142-50 wall-mounted arm lets end users attach the monitor of their choice. After installation, it can be positioned with 344 mm of vertical movement for the best viewing angle based on user height. Adding the AV–D40–33A144–50 single arm allows the monitor to tilt and swivel, decreasing the risk of glare and user fatigue due to changing working conditions.

With an arm that can withstand strong touch forces, vibration, and heavy loads, the AV series proved to be the perfect fit. Southco's ergonomic solution reliably holds the monitors of various weights in a neutral position.

Lastly, a removable cover allows power and display cables to be hidden within the application, removing snag hazards and allowing users to keep their workspace permanently clear of clutter.

Producers Peanut Optimizes Peanut Drying with Moisture Monitoring System from WECO

Producers Peanut, a Georgia-based buying point for Premium Peanut, recently updated its processes in 2023 buy installing WECO's PeanutTek active moisture monitoring system, which provides continuous in-shell moisture readings to enhance product quality.

Traditionally, the peanut industry relied on manual sampling to monitor moisture levels during drying.

According to Ron Dozier, General Manager at Producers Peanut, the company "had people using ladders to climb on top of trailers and get gallon-size samples" and they were collecting samples several times per load. After witnessing other types of nut processors that used sensor plates to monitor moisture during drying, the company knew it needed to find a supplier.

PeanutTek uses a series of sensor plates installed in each semi-trailer or wagon to collect moisture data from a large sample size. The sensor plates continuously monitor the moisture content of the peanuts during the drying process, sending data to a computer. The system can automatically turn off burners when the moisture of a load reaches a predetermined set point, ensuring consistent drying. PeanutTek also provides up-to-date dryer temperatures, so operators can stay ahead of maintenance by fine-tuning gas pressure for maximum efficiency.

"PeanutTek has drastically improved our drying process,” said Dozier. “Now, we simply connect the load to the dryer and hook it up to the WECO system. No more climbing on trailers, collecting sample buckets and shelling the peanuts to determine the status. We get live moisture readings that I can monitor from my office, home, or smart device, and I can even adjust settings remotely. Once the load reaches the desired moisture level, PeanutTek turns the dryer off instantly.”

Producers Peanut has also seen enhancements to product quality since implementing their PeanutTek system. By sampling a wider zone consistently and turning dryers off at precisely the right time, it achieves a more reliable moisture reading and superior dry time compared to traditional, manual methods. This improved precision is especially valuable for Producers Peanut’s seed peanut products, which require especially specific moisture levels to preserve germination potential. “Plus, by optimizing the drying process, PeanutTek has helped us cut down on energy consumption, which reduces our operational costs and aligns with the market trend toward sustainability,” said Dozier.

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.