Inventive RAM Reverse Airflow Motor Technology

Bison has announced the issuance of a patent for its RAM Reverse Air Movement Blower Motor. This invention, spearheaded by Senior Director of Technology, David Finkenbinder, overcomes the performance shortcomings of traditional thru-flow air blower motors through its new design.

RAM technology can transform various air-moving applications, catering to industries that prioritize lower operating temperatures, achieving reduced noise and extended motor life. This innovative technology can benefit applications from industrial fume evacuation, floor care for commercial and residential use, paint sprayers, aerospace air movement, surgical smoke evacuation, and hand dryers.

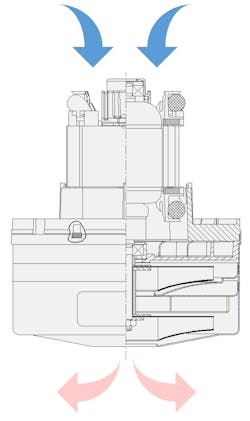

Unlike traditional thru-flow motors that face overheating challenges, RAM employs a reverse airflow design. The motor side is only exposed to ambient air intake for optimal cooling even in near-sealed conditions. This eliminates the need for thermal protection or bleed holes, enhancing reliability, sound performance, and motor life.

Motors with RAM operate at significantly cooler temperatures, enhancing brush life, commutator performance, and reliability. The technology achieves a 6.5% reduction in decibel levels and a 48% reduction in Sones compared to traditional thru-flow motors. RAM technology also removes the need for a leak path at low flow conditions, leading to better product performance and reduced noise.

The motors support straight air exit, peripheral, and reverse airflow, providing many solutions for various applications. The technology can also reduce carbon dust emissions by applying V0-rated foam to surround the motor to improve performance and minimize noise.

The product is available in a range of custom design options, providing lightweight applications, shorter heights, and larger diameters to meet specific end-use requirements.

Price: Contact the company for pricing

Bison | a Division of Ametek

Kent, OH

www.bisonametek.com