Clean-Tech Machining With Ionized Air Technology

Aurion Machining Technologies has developed a new technology using ionized air creating a trailblazing clean-tech alternative for metalworking fluids and emulsions in parts manufacturing.

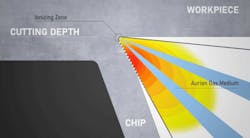

The core of the Aurion technology is in the ionized air which generates an electrochemical process resulting in electron loss and atomic level transformation of Aurion gas medium at the cutting surface. The electrochemical process acts as a dry lubricant in the cutting process, penetrating the cutting zone and optimizing the interaction between the tool edge and the workpiece. This process accelerates oxide layer formation and significantly reduces friction, thermal stress, and tool wear.

The Aurion system consists of 3 components: an ionizer, a controller, and an air-cooling unit. The system is connected to the factory's compressed air network and machinery CNC. There's no need for any special safety precautions as ionized air pressure remains at 2 to 3 bar and temperatures of -10 to 10°C during machining operations.

Aurion reduces manufacturing costs and cutting lead times in workshop processes. Thousands of validation runs have proven that Aurion technology delivers at least the same machining quality and performance as cutting fluids—measured by cutting speed, tool life, and surface quality. Ionized clean air is safe for its operators and the relevant machinery and meets the highest standards for workpiece residuals.

It's suitable for all machining applications and materials and is easy to integrate into both existing and new machines, either by using the external piping to the cutting zone or by using existing coolant channels in standard tool holders and tools.

High integration flexibility and the possibility to use existing machine tool features minimize the up-front investment and limit the transition costs for introduction of the Aurion technology. The payback for the Aurion system is typically 3 to 6 months.

Features:

- Uses ionized air as a lubricant in the cutting zone

- Uses a dedicated ionized air unit with built-in electronics and integrated software

- The system has no mechanical or electrical wear parts

- Comprehensive IPR protection

Aurion Machining Technology

Finland

www.aurion.fi