Rösler PowerLine Valve Enables Intelligent Shot Blasting

With its PowerLine valve, Rösler has improved turbine shot blasting operations. The intelligent shell valve ensures that the blast intensity of turbines is automatically adjusted to different shot blasting requirements for optimal operating conditions. The adjustment takes place independently from the turbine RPM and without manual adjustment of the blast media flow, eliminating any operator error.

The turbines are the centerpiece of shot blast machines and determine to a large extent the blast performance, the required cycle times, and the costs of a shot blast process. The shell valve allows the automatic, optimal adjustment and control of the blast performance independently from the turbine RPM.

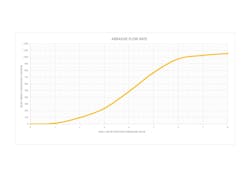

At the heart of this patent-pending system is an innovative shell valve. Through special sensors, the valve opening is automatically adjusted to the specified blast media flow. To determine the opening, a specially developed software takes the parameters amperage draw, taking speed and blast media flow into consideration. The software allows the automatic creation of separate programs for each turbine within a few minutes. All the operator has to do is enter the optimal operating parameters for the respective shot blast process, such as throwing speed, blast media flow, or amperage draw, at the operating panel. If, for example, a high workpiece throughput is required, the operator can increase the blast media flow and the throwing speed. At the same time, for processing delicate workpieces, operators can reduce the media flow and throwing speed.

In everyday shot blasting operations, the PowerLine valve results in shorter cycle times. Individual shot blast programs for new workpieces can be easily created and saved in the PLC. Complex shot blast processes requiring different blast media flow quantities can be quickly implemented without any problems.

The Rösler system also offers advantages for shot peening operations with short cycle times by reducing the setup times for the respective peening process. Additionally, the automatic monitoring and documentation of the blast media flow provide proof that a given shot blast process has been run with precisely defined parameters.

Rösler Surface Technology GmbH

Untermerzbach, Germany

+49 9533 924802

[email protected]

www.rosler.com