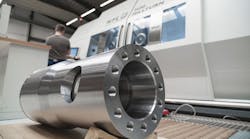

A line of milling solutions tailored to meet the distinct demands of the wind energy sector and process industry offers advanced capabilities for longitudinal, circumferential, and edge beveling. Including PEMA LM, PEMA CM, and PEMA EB, the product family incorporates a Direct Drive spindle technology.

The LM milling machine for longitudinal milling enables pre-programmable milling cycles for different thicknesses as well as integrated rollers for workpiece rotation. Capable of milling to depths of 140 mm, the PEMA CM for circumferential milling and PEMA LM for longitudinal milling are suitable for preparing narrow gap grooves.

The EB edge beveling system offers plate edge milling and preparation, automatic milling cycles, high monitoring precision, and a plate edge scanning function for milling path alignment.

All 3 machines feature Direct Drive spindle technology, driven by servos and devoid of backlash, offering less vibration and more lifetime for milling inserts.

PEMA LM:

- Compact design

- Optimized performance for thick materials

- High torque spindle

- Advanced control system

- Automated working sequences

- Integrated rollers for workpiece rotation

- Enables milling of satellites in the same process

- Improved milling quality

PEMA CM:

- Optimized performance for thick materials

- High torque spindle

- Milling depth up to 140 mm

- Fast setup time

- Movable with an overhead crane or forklift

- Preset milling parameters

- Interface to material handling equipment

- Advanced control system

PEMA EB:

- Optimized performance for thick materials

- High torque spindle

- Plate edge scanning function for milling path alignment

- Plate loading with a robust conveyor system

- Advanced control system

- Direct Drive technology by KESSLER

Pemamek Ltd.