How Lasers Help to Win the War Against Corrosion

Industries have been fighting a war against corrosion in metal infrastructure, equipment, and products at great expense for generations. “The global cost of corrosion is estimated to be U.S. $2.5 trillion, which is equivalent to 3.4% of the global Gross Domestic Product (GDP) (2013), according to a NACE International IMPACT study to examine the current role of corrosion management in industry and government and to establish best practices.

Given the massive industrial outlay, proactively controlling corrosion is imperative and can have an equally impressive ROI.

“By using available corrosion control practices, it is estimated that savings of between 15 and 35% of the cost of corrosion could be realized, i.e., between U.S. $375 and $875 billion annually on a global basis. The fact that corrosion control provides a cost-benefit is a lesson learned over and over again by industry, often too late and following catastrophic events,” continues the NACE International IMPACT study.

However, traditional methods of removing corrosion can be messy, laborious, time-consuming, and can even pose serious health hazards.

Today, one of the easiest to use and most effective alternatives in the war against corrosion is the increasingly important category of industrial-grade, clean technology lasers.

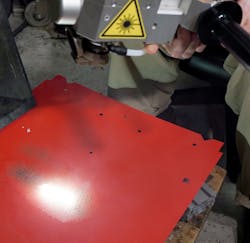

With this approach, precision laser-based systems are used to remove corrosion, contaminants, paint, and residues with a high-energy laser beam that leaves the substrate unaffected. Preparation and cleanup time are minimal, and the low-maintenance equipment can last decades. The technology minimizes operator exposure to potential environmental health hazards. In addition, no consumables are necessary.

Corrosion and the Limits of Conventional Control

Any industry with metal infrastructure, processing equipment, or products exposed to water, fluids, moisture or atmospheric humidity continually fights corrosion, which causes the deterioration and loss of a material and its critical properties due to chemical, and electrochemical reactions of the exposed surface with the surrounding environment. Corrosion affects the microstructure, mechanical properties, and physical appearance of the materials.

The direct cost of corrosion includes a loss of materials, equipment, and production, plus the cost of repair, maintenance, and replacement. Additional losses can result from accidents, injuries, and even loss of life as well as payments to repair environmental damage.

Within the continual struggle against industrial corrosion, one important niche area of corrosion control involves the pretreating of metal surfaces to remove corrosion and contaminants before coating or welding.

Although metal surface pretreatment is a small portion of industrial corrosion control, it is crucial to ensure the safety, performance, and longevity of products and structures.

Insufficient coating pretreatment can lead to inadequate protection from the environment, leading to potential coating failure, moisture entry, and accelerated corrosion as well as increased maintenance, early replacement, and warranty issues. Similarly, insufficient weld pretreatment to remove corrosion and contaminants can lead to weakened or failed welds and necessary rework as well as substantial safety, liability, and litigation risk.

A More Effective Weapon to Eliminate Corrosion

In many industries, it is necessary to remove corrosion, residue, oil, grease, or paint before coating a product or infrastructure to improve coating adhesion.

Toward this end, laser-based systems have significant advantages over traditional methods, starting with ease of use.

“With laser-based systems, an operator simply points and clicks a high-energy laser beam at the surface. The substrate is not affected by the laser, and the systems do not create any mess or byproducts. The approach is eco-friendly, energy-efficient, and completes the job in approximately half the time of traditional methods when preparation and cleanup are considered. Also, no consumables are required,” says Wayne Tupuola, CEO, Orlando, Florida-based Laser Photonics, a leading provider of patented industrial-grade CleanTech lasers for cleaning and surface conditioning. The company’s systems function either as mobile standalone units or can be integrated into production lines.

In the case of Laser Photonics, the laser systems are available in portable and stationary models ranging from 50 to 3,000 watts (a 4,000-watt version is in development) with chamber sizes from 3 x 3 feet (1 x 1 meter) in size to 6 x 12 feet (2 x 4 meters). The systems can also be installed in manufacturing lines in cabinets or operated by a robotic arm.

In industry, the laser pre-treatment of metal surfaces can be used to streamline various manufacturing processes. For instance, it has been used to remove rust from hundreds of automotive transmissions per day. It has also been utilized to eliminate corrosion from conveying system components.

The CleanTech lasers are also used to refurbish industrial infrastructure, such as when removing a previous coating along with any corrosion to facilitate the new coating’s adhesion to the surface.

Another common laser application involves pre-weld treatment to remove corrosion, mill scale, residue, and any impurities on the surface of the base material that would compromise the weld’s effectiveness. It is essential to avoid any such contamination on a weld’s surface, which could otherwise lead to a weakening of the weld’s mechanical properties, requiring rework.

Laser treatment is also used for post-weld cleaning to increase the life expectancy and corrosion resistance of a welded joint. Post-weld cleaning is important for stainless steel as well. Welding can cause a “heat tint,” a discolored, thickened top layer on the stainless steel around the weld bead within the heat-affected zone that compromises corrosion resistance. Removing the heat-tinted top layer is necessary to restore stainless steel’s full corrosion resistance and aesthetic value.

A further benefit of the laser system is that some of the most advanced units are designed to last for decades. For example, CleanTech laser systems can last for 50,000 to 100,000 hours. In addition, virtually no maintenance is needed after purchase and no consumables are required.

Given the devastating cost of corrosion to industry and the inherent limitations of typical control methods, lasers are becoming a best practice technique to combat it in facilities and in the field. Laser treatment effectively removes corrosion for many industrial applications, minimizes cleanup time and operator exposure to potential environmental health hazards, lasts for decades, and requires no consumables.

For more information on laser cleaning solutions for surface preparation, contact Laser Photonics at (407) 804-1000 or visit www.laserphotonics.com.

About the Author

Del Williams

Del Williams is a technical writer based in Torrance, California. He writes about health, business, technology, and educational issues and has an M.A. in English from C.S.U. Dominguez Hills.