6 Fixed Gas Detection Innovations To Consider for Safer Facilities

(Download this article in .PDF format by clicking the download button at the end of the article.)

The dangers of undetected combustible and toxic gases in hazardous industries are well-known to process and plant engineers. Safety is Job #1 in these industries because the consequences of an accident can be devastating. The safety industry, therefore, continuously focuses on developing effective sensor technologies for combustible and toxic gas monitoring.

The Problems

The three major user complaints about fixed gas detection equipment that cause the most problems for plant teams in hazardous industries can be summarized as:

- Frequent sensor replacements

- Installation and maintenance challenges

- Integration with plant control systems

To address these and other issues, there are six emerging technology trends in fixed gas detection systems that are worth considering:

1. Electrochemical Cell Sensor Advances

The new generation of XCell sensors with TruCal technology by MSA saves time and money by offering higher performance (faster response times) and a longer life that is double the industry average. They also automate much of the hard work previously performed by technicians during installation with plug-and-play capability and less maintenance.

These next-gen electrochemical cells have been designed with pulse check technology and Adaptive Environmental Compensation (AEC) algorithms. With built-in TruCal technology, they provide peace of mind like never before when it comes to assuring continuous proper calibration to avoid missed or false alarms that can result in accidents or reduced productivity.

Automated pulse checks are the muscle behind TruCal technology. Every six hours, an electrical pulse stimulates the sensor, similar to having actual calibration gas applied, providing a snapshot of the sensor’s sensitivity at the time of the pulse. Using this sensitivity snapshot, the sensor can: •

- Validate that the sensor is operating normally

- Compensate for sensitivity drift due to changing environmental conditions

- Recommend when a calibration should be performed

- Warn when the sensor will need to be replaced in the near future (2 to 3 months)

- Report the life and health status of the sensor as “Good” or “Fair”

- Initiate a “Fault” alert indicating the sensor is no longer monitoring effectively

2. Laser-Based Open Path Gas Detectors

Another trend to watch is a relatively new open path detection sensor technology that is an excellent solution for monitoring large areas or perimeters where point detection would be too costly or impractical. Senscient ELDS Open Path Gas Monitors (Fig. 1) with enhanced laser diode spectroscopy (ELDS) sensing can detect either flammable or toxic gases with remarkable specificity.

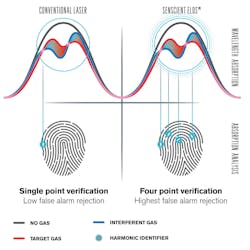

In the event of a gas leak, the sensor’s laser technology detects the Harmonic Fingerprint produced by the target gas’s absorption of the laser light. The harmonics produced through absorption of the laser light are as unique to the gas as a human fingerprint is to an individual, thereby providing a level of false alarm immunity unmatched by other gas detection technologies (Fig. 2).

Critical to any open path detector’s functionality is to maintain a clear path between the transmitter and receiver, which can prove very challenging in outdoor applications. These ELDS Class 1 eye-safe lasers are used to penetrate thick fog, heavy rain, and snow beyond the capability of traditional open-path infrared (OPIR) detectors. They are an excellent alternative to nondispersive infrared (NDIR) gas detectors where harsh weather is a maintenance issue.

3. Onboard Diagnostics-Ease of Maintenance

Simplifying and reducing the cost of maintaining fixed gas detectors is a major focus. The routine calibration checks required by gas detectors are largely a manual task performed by technicians who must carry special tools, test gas cylinders, and more with them. Spare gas sensors and other parts also must be stocked, stored, and inventoried to be ready for use.

That’s no longer the case with the arrival of onboard diagnostic capabilities in the latest generation of electrochemical cells and laser-based gas detectors (as mentioned previously). New intelligent technologies are performing routine calibration self-checks and calibration adjustments first and then alerting technicians should a sensor need eventual replacement. This allows plant technicians to attend to other tasks throughout the plant, increasing their productivity.

4. Wireless Bluetooth

New communication protocols such as Bluetooth and industrial plant apps now make it possible for instrumentation technicians to communicate with gas detectors from safe areas. Employee falls are one of the most common causes of accidents in process and manufacturing plants, and performing gas detector maintenance can be a hazard in itself.

Fixed gas detection monitoring systems are often located and directed in high or other hard-to-access locations near piping or valves and other critical equipment that must be monitored continuously for gas leaks. Until now, that meant using open stairways or scaffolding with safety harnesses. With the improved security of wireless technology, optional Bluetooth communications have been added to the Ultima X5000, General Monitors S5000, and Senscient ELDS gas detectors.

Technicians with mobile devices and HMI screens now have a controller at their fingertips for added safety and convenience, especially in difficult-to-reach locations.

5. Data and Communications

The evolution of standardized digital communications, such as the HART protocol, offers many advantages to plant and corporate teams in terms of bringing the right data to the right systems. HART protocol, for example, provides process information to DCS, PLC, and other plant control systems that can issue safety alerts in the event of a gas leak and initiate gradual plant shut-downs based on those alerts, compile event data, and more.

The HART 7 protocol is now available on MSA’s newer gas detectors. That means XCell Sensors are capable of sending sensor status via HART into a plant’s preventative maintenance system, further automating the sensor maintenance process.

6. Dual Gas Sensor Transmitters

Until now, most fixed gas detection systems have been constructed with discrete electrochemical, catalytic bead, metal oxide semiconductor (MOS) or point infrared (IR) detectors. That was fine if you were concerned only about one gas, but what if you needed to monitor two different gases?

Plant operators had to buy two individual transmitters, wire them up and commission them. They also had to maintain both of them—test, clean or replace sensors, recalibrate, and bring them both back online. The electrical wiring and maintenance expenses ended up being more expensive than the monitor itself.

That’s changing with dual sensor transmitter designs for fixed gas detectors. For example, a gas monitor (Fig. 3) with a dual sensor design doubles its capabilities while requiring 50% less wiring and conduit than a single gas transmitter for equivalent sensing coverage. Making it less expensive to monitor gases encourages operators to install more comprehensive plant gas detection systems.

Conclusions

Safety will always be Job #1 in hazardous industries where combustible and toxic gases are potentially present. MSA has a long history of innovation and recognizes the need to continuously improve performance, increase reliability and simplify use and maintenance.

If you’re planning to upgrade, retrofit or expand your facility, make fixed gas detection one of the first priorities and turn to MSA’s trusted safety professionals who can help optimize gas monitoring at your plant.