Latest from Quality Control

New Article

AI-Powered, HD 3D Scanning

Quality Management Software Release

How to Track Maintenance Costs

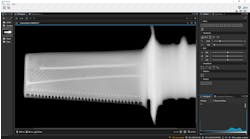

X-Ray Inspection Made Easy

Pyrometer Series Extended

High-Speed IR Camera

Multifunctional Thermal Flowmeter

Back on Track with Oil Analysis

ETALON‘s LaserTracer was developed for sub-micron-accurate geometric analysis, monitoring and accuracy improvement of machine tools and measuring machines. It is a self-tracking laser interferometer that automatically tracks a reflector, and hence allows for identification of geometrical deviations with highest precision. The compensation data determined by the system can be directly imported into the control software of the machine or CMM.

The follow-up model LaserTracer-NG is a redesigned system that consolidates Etalon’s experiences gained during the last ten years of machine calibration.

The LaserTracer-NG is smaller, weighs less and offers a larger angular range. Thus, it facilitates measurement in limited machine space. Moreover, it can deal with highly dynamic machine movements: The accelerations of the machine permitted during measurement have nearly doubled.

Factory-floor suitability was a major aspect of the redesign effort. Originally, the LaserTracer had mainly been used under laboratory conditions. In recent years, it has been developed for into production applications, and now faces much harsher conditions. To prepare the new LaserTracer-NG for this challenging environment, it is equipped with a closed housing, just two connectors and a more flexible cable.

The LaserTracer-NG, like the previous model, features an unprecedented accuracy of the center of rotation thanks to a patented measurement technique: A sphere with a form deviation of just 50 nanometers is used as an optical reference for the interferometer. As a consequence, the mechanical errors of the rotation and swivel axes are fully compensated.

For measuring, the LaserTracer-NG is stationary placed at several different positions inside the working volume of the machine. Then, the reflector is mounted to the tool or probe. In the following automated measuring process, the system tracks the actual path of the machine in its entire working volume. Meanwhile, the system acquires precise measurement values that are processed and analyzed by Etalon’s software package Trac-Cal.