NEXTEC LASER METROLOGY LLC is offering a 3D multi-position laser inspection system — WIZinspect — that allows manufacturers to improve the quality control process with more speed and higher precision, while lowering cost and setup time. WIZinspect can be integrated with factory floor automation to provide an in-process turnkey inspection solution where users can achieve 100% inspection of components, even in high productivity environments such as automotive and other high volume industries.

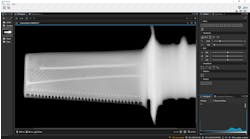

WIZinspect is based upon Nextec’s vision and laser technologies, wtih patented optics and image processing for fast, accurate and reliable scanning and geometric measurements. The large dynamic range and high accuracy of the probe make it easy to set up the alignment loop and measurement paths to collect hundreds of points quickly and accurately. This WIZinspect solution provides a total system precision of less than 14 microns.

With WIZinspect, a new part is easy to program and setup in the system with the user-friendly soft keys software and the part CAD model. The WIZinspect system performs part alignment, inspects all required dimensions and delivers detailed reports of the measured dimensions plus success or failure output based on relevant part tolerances.

To accommodate varying part geometries and sizes, Nextec supplies a variety of 3-axis motion platforms and optional rotary tables.