Latest from Quality Control

New Article

AI-Powered, HD 3D Scanning

Quality Management Software Release

How to Track Maintenance Costs

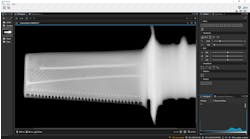

X-Ray Inspection Made Easy

Pyrometer Series Extended

High-Speed IR Camera

Multifunctional Thermal Flowmeter

Back on Track with Oil Analysis

Earlier this year, COORD3 INDUSTRIES launched its ‘Universal’ line of coordinate measuring machines: now, it is introducing the European-manufactured Universal CMMs to North America. It uses a high-tech alloy, moving-frame design for dynamic, accurate measuring performance. This design overcomes the issues associated with operating traditional granite CMM structures in the typical, less-than-perfect operating environments.

In addition, the Universal CMM incorporates a wireless thermal compensation system of both machine and part, allowing the measuring system to compensate for changes in the CMM operating environment, automatically and dynamically. This system allows the CMM to perform accurately between 16° and 26°C. Gold-plated 0.1 µm measuring scales are free-floating in support tracks, eliminating any CMM structural changes from influencing its measuring accuracy.

The COORD3 Universal CMMs provide a rigid structural coordinate measuring platform, allowing the use of point-to-point, analog contact scanning and laser scanning sensors, making it ideal for full 5-axis and gear measuring applications.

The CMMs have an isostatic design for each axis that provides optimal geometric alignment in the construction of the machine, which aids the effort to make accurate field calibrations. Universal has a monolithic base-plate, with integral inverted dovetail guide-way, and a generous 90x90 mm (3.5 x 3.5 in) Z-ram section providing metrological performances. Direct axis drives, using toothed drive belts, provide the vibration-free motion with zero hysteresis.

Universal CMMs can be equipped with an optional SZP (safety zone protection system) that uses laser scanners to monitor the defined protection zone when the CMM is in high-speed automatic measuring mode. SZP reduces the CMM speed upon infringement of the safety zone by an operator, and automatically returns the CMM to its full measuring speed only after the zone infringement has been cleared. The SZP system allows safe use of the CMM in production, shop-floor, and fully-automated applications.

The higher accuracy Nano Technology version of the Universal CMM uses a silicon-carbide Z-ram and enhanced measuring scale system to provide higher-speed, enhanced scanning accuracy with a 0.3 µmreduction in measuring uncertainty.

COORD3 Universal CMM machines are available with measuring strokes for the X-axis of 1,500 mm (59-in.), 2,000 mm (79-in.), 2,500 mm (98-in.) and 3,000 mm (118-in.); Y-axis of 1,000 (39-in.) and 1,500 mm (59-in.); and Z-axis of 900 (35-in.) and 1,000 (39-in.) mm.

Visit www.coord3.it