Alcoa reported it has entered into its largest-ever supply contract for aerospace fastener products with Airbus SAS, valued at approximately $1 billion and involving products in multiple materials and concerning every Airbus platform. The Alcoa Fastening Systems & Rings business develops and produces specialty fasteners, fluid fittings, assembly components, installation systems, and seamless rings for aerospace and industrial applications.

The supplier did not report when the contract will take effect or how long it will continue. It noted that several of the fasteners to be supplied will be proprietary products developed specifically for Airbus.

Alcoa already is supplying Airbus according to earlier long-term agreements, including one involving aluminum sheet, plate, and hard-alloy extrusions, and a separate one concerning titanium and aluminum forgings for aerospace products.

The aerospace market has been a particular focus of Alcoa in the past two years, during which it has invested in new capacity and capabilities at its existing forging and investment casting operations, and acquired new capabilities via acquisitions of Firth Rixson Ltd., Tital, and RTI International Metals. Alcoa chairman and CEO Klaus Kleinfeld cited that strategy as one factor that contributed to the recent decision to spin off Alcoa’s downstream operations in 2016.

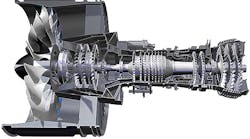

In particular the commercial aerospace sector, a market in which Airbus is one of two dominant manufacturers, has been expanding steadily in the past decade, a pattern that is forecast to continue for the remainder of this decade as new aircraft series and new jet engine models are introduced. High levels of demand are being driven by existing carriers replacing aging jet fleets and new carriers emerging to serve growing passenger and freight traffic in Asia and Latin America.

Alcoa noted that in the new agreement it will supply fastening systems used to assembly aircraft panels and engine pylons on newer aircraft series that incorporate more advanced design details. Efforts to make new aircraft series lighter and more fuel-efficient have resulted in OEMs adopting new aeronautic design elements and advanced materials, like carbon-fiber composites, titanium alloys, and aluminum-lithium alloys.

The fasteners are produced at 14 Alcoa plants around the world, in various materials like stainless steel, titanium, and nickel-based superalloys that improve fatigue life and achieve “lightning strike protection," and improve wear and reusability on conventional and composite aircraft.

“Our growing aerospace capabilities, technology strength and global, first-rate customer service continue to strengthen Alcoa’s decades-long partnership with Airbus,” according to Kleinfeld.