The European forging industry employed around 70,000 people in 2012, producing nearly 6 billion metric tons of forgings with an annual turnover of approximately €12 billion. These are about 22.5% of the world’s forging production[Eur12]. The main components of the production costs are material and energy costs. The material costs sum up to 50% for parts made of steel[Rit09] and increase up to 90% for forged parts made of titanium[Lue07].

Additionally the forging industry consumes the most energy compared with other manufacturer of metal products.

Therefore, in this area the potential for savings is very high. According to the latest investigations concerning potential for material and energy reduction in Germany, material savings up to €2.3 billion and energy savings up to €631 million per year are possible[VDI13].

Whether producing engine parts, turbine blades, or hip implants, during production of forging parts with a long geometry, material is the main component of the production costs — especially if valuable materials like titanium or high-alloyed steels are used. Most parts are forged in dies in several steps, with a high amount of flash. One way to save valuable material, especially for long forgings is to use cross-wedge rolling (CWR) as the first preform operation.

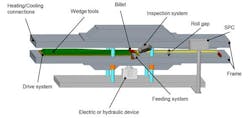

In CWR, the basic movements that the dies have to provide are in opposite directions. The billet is located in the middle of the tools and remains there during the whole rolling process as the material is distributed along its axis.

The CWR tools can be designed in round and flat wedge tool configuration. The main advantage of round CWR wedges (see Figure 1, left) is that a high batch production (mass production) is possible. However, the tool technology is difficult and the round wedge tools are very expensive, depending on size and geometry. The use of flat wedge tools (see Figure 1, right) is an economical alternative due to less expansive tools, and therefor attractive for SMEs.

CWR machines for industrial processes are almost exclusively expensive machines with round wedge tools. Especially for SMEs this technology brings several challenges:

• Lack of knowledge concerning the design of CWR processes;

• Missing knowledge about the boundary conditions of rolling valuable materials;

• Missing alternatives for economic CWR machines for small and medium-batch output; and

• No quality control to ensure fault-free production.

To overcome these challenges a new research project, called CoVaForm (“Conservation of Valuable materials by a highly efficient Forming system”) was initiated. The project was founded by the EU, started January 1, 2014 and will last for a period of two years. The project consortium consists of four enterprises and three research institutes from Germany, Spain, Italy, Austria, and Turkey.

Identifying a New Process Sequence

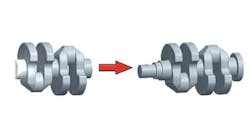

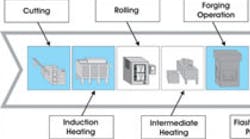

The above-mentioned challenges will be overcome by developing a new, resource-efficient process chain for forging parts made of steel and titanium. The investigated parts are long parts with irregular mass distribution along the main axis (see Figure 2.) Particularly for such parts, the design of a reduced-flash forging sequence is very difficult. Especially for titanium it has not been investigated so far.

In order to achieve significant flash reduction, the process chain to be developed includes a CWR preforming operation and an adaption of the final forming dies (see Figure 3.) Thus, a material utilization of nearly 100 % in preforming and up to 80 % in final forming can be obtained.

Designing CWR processes requires a lot of specific knowledge. Therefore, most SMEs do not use this technology due to missing experience regarding e.g., the rolling requirements or the possible influence on the entire process chain. The first challenge is gaining knowledge of CWR in order to design a working CWR process. This knowledge is mandatory for identifying critical process parameters in order to avoid possible defects that may occur in a CWR process. Only with a reliable process design the high economic advantages of CWR can be gained.

Additionally, the influence of a cross-wedge-rolled part on the subsequent forging step has to be investigated and possible adjustments on the forging tools have to be determined. Although the CWR technology has a lot of advantages, it has not been widely accepted throughout the forging community.

One of the main reasons is the complexity of CWR tooling design. The design is difficult because of potential failure mechanisms that can be encountered during CWR processes. These failure mechanisms can be separated into three distinct categories[Joh77]: surface defects, internal defects, and improperly formed workpiece cross sections.

Newer developments on the CWR process and the simulation of this process by modern finite element analysis (FEA) software allow the prediction of those defects under different circumstances and give a good expertise in these processes. In order to enable SMEs to use this technology, an easy-to-use CWR process design method will be developed that will enable inexperienced users to design CWR processes on their own.

The investigation of CWR for new materials is the second challenge. Since CWR for titanium is unknown (until today), another project objective is to investigate CWR for new materials and develop a working process by practical tests and the application of modern numerical simulation tools (FEA.) The intention is to find boundary conditions in which the rolling of valuable materials is possible.

A Flexible, Modular Design

First research steps were done, e.g. investigating the basic feasibility and failure mechanisms of CWR of titanium[Cak12] [Neu08]. The production of titanium parts in small batches using a flexible machine and a fast layout method, as well as a temperature and defect measurement, have not yet been investigated.

To overcome the economic disadvantages of expensive machines with round wedge tools, a CWR machine with flat wedge tools will be developed, which will be economic especially at small and medium batch sizes (see Figure 4.) The machine will be designed according to the needs of SMEs, such as easy tool change and low tool costs, which is this third challenge.

Today, flat wedge tools are mostly used in industrial processes to produce screw threads[Tsc10]. Machines with flat wedge tools are available only outside the EU from just a few manufacturers. These machines are still quite expensive and not designed modularly, do not provide in-process quality control capabilities and thus are not advantageous for SMEs. Modular CWR technology is needed by European SMEs, so they are able to use the CWR with flat wedges e.g. in a frame or in a hydraulic press.

During the now completed “DeVaPro” project (FP7-SME-2007-1, No. 221967) a CWR module was developed that can be mounted in a hydraulic press to get an easy and low-cost option for using CWR technology in a flat wedge configuration[Kac10]. The costs of these flat wedge tools are much lower and do not have any disadvantage compared to the round wedge tools. The tools in this configuration worked but the module was not designed for industrial use in the first place.

Furthermore a hydraulic press is necessary to maintain pressure between the tools and the billet. The new CWR machine to be developed in the current project will not need a hydraulic press to maintain pressure. Instead, a hydraulic or electric device will be used to enable the needed press force.

Addressing the importance of stable workpiece temperature for CWR, a method for reliable measurement is required, which resembles the last challenge. In order to avoid any interference to the CWR process all measurement and inspection methods are supposed to work without any physical contact to the workpiece. Thus, thermography will be used as process monitoring technology to measure the workpiece temperature and, in addition, inspect the cross-wedge rolled parts in order to detect surface defects.

Heat flux-based thermography works in an automated and non-contact way by acquiring a sequence of thermal images of the sample surface while heat dissipates through the part. Flaws within the material, such as cracks or voids, will result in different rates of heat dissipation compared to normal structure. Using the resulting irregularities in the images surface as well as inner defects may be detected. Based on this principle many applications are already known[Vav94, Mal10]. With this technology, fast and direct quality control of the workpiece is possible. Defective parts can be detected during the CWR process and removed from the forming process before going to the next process step. In this way, the energy used for subsequent forming operations can be saved and therefore the overall energy consumption reduced.

CWR for High-Value Materials

The production of titanium parts in small batches using a flexible machine and a quick set-up method, as well as a temperature and defect measurement, have not been considered in investigations yet. However, manufacturers using valuable materials have shown interest in this technology and the CWR module in order to realize the advantages of the CWR technology for small and medium batch sizes.

Therefore a CWR-machine for flat wedge tools will be developed in the EU project CoVaForm. The wedge tools used in this project will be designed for rolling titanium and micro-alloyed steel. To help SMEs, a software tool will be developed for designing CWR processes. Especially for rolling valuable materials like titanium, the boundary conditions are mostly unknown; therefore pre-tests will be done to get process parameters that will enable a working CWR process.

To ensure a fault-free production, quality control standards will be developed based on thermography that detects faulty parts directly during the rolling operation.

The research leading to these results received funding from the European Union’s Seventh Framework Program, managed by REA-Research Executive Agency (FP7/2007-2013) under grant agreement No. 606171 FP7-SME-2013-1.

The authors are affiliated with Institut für Integrierte Produktion Hannover GmbH in Hanover, Germany. Dipl.-Ing. Thoms Blohm is the project engineer, IPH ([email protected]); Dr.-Ing. Malte Stonis is the manager for Process Technology, IPH, and Prof. Dr.-Ing. B.-A. Behrens is a member of the management board, IPH. Visit www.iph-hannover.de or www.covaform.eu for more information

References

[Cak12] — Çakircali, M. et al.: Cross wedge rolling of a Ti6Al4V (ELI) alloy: The experimental studies and the finite element simulation of the deformation and failure. International Journal of Advanced Manufacturing Technology, Springer Verlag, published online first, 6 June 2012.

[Eur12] — EuroFORGE (2012) 2012 worldwide survey; Accessed 26 February 2014

[Joh77] — Johnson, W.; Mamalis A. G.: "A survey of some physical defects arising in metal working processes," 17th International MTDR Conference, London 1977, pp.607-621.

[Kac10] — Kache, H.; Nickel, R.: Cross wedge rolling in the warm temperature field as a trend setting forging technology, 30.10.2012.

[Lue07] — Lütjering, G., Williams, J. C.; Titanium. 2nd Edition, Springer Verlag, Berlin u. a. 2007

[Mal10] — Maldague, X.: Theory and practice of infrared technology for nondestructive testing, John Wiley & Sons, London 2001.

[Neu08] — Neugebauer, R. et al.: "Cross wedge rolling in preforming titanium alloy aero engine vanes." Steel research int. 70, special edition metal forming conference 2008, vol. 1 (2008), pp. 375-381.

[Rit09] — Ritter, C: Impulsprogramm Materialeffizienz macht Unternehmen fit für den Wettbewerb. Intelligenter Produzieren, o.Jg.(2009), H.4, S.40

[Tsc10] — Tschätsch, H.; Dietrich, J.: Praxis der Umformtechnik: Arbeitsverfahren, Maschinen, Werkzeuge. 10 Auflage. Vieweg + Teubner, Wiesbaden 2010.

[Vav94] — Vavilov, V. P.: Infrared Methodology and Technology. Taylor and Francis Ltd., London 1994.

[VDI13] —Seliger, G., Emec, S., Stock, T., Bilge, P., Tufinkgi, P., Kaden, C.; Studie: "Analyse von Potenzialen der Material- und Energieeffizienz in ausgewählten Branchen der Metall verarbeitenden Industrie," VDI Zentrum Ressourceneffizienz GmbH, Berlin, 2013