Kobe Aluminum Automotive Products LLC, Bowling Green, Ky., has doubled its production capacity with the addition of a new melting/casting line and two 6,300-ton forging presses. It is the fourth expansion since the plant started operating in 2005. It brings to six the number of mechanical forging presses in operation there, producing aluminum automotive suspension parts.

Kobe Steel Ltd., KAAP’s parent company, reported the latest investment at $66 million, and noted the new capacity at that location is more than 5 million pieces annually (420,000/month.)

A 150,000-sq.ft. extension to the plant also was built to house the new capacity, adjacent to the existing plant. The company also added 50 new employees with the new capacity, bringing the plant’s total to 350.

KAAP is a joint venture of Kobe Steel, Mitsui & Co. Ltd,. and Toyota Tsusho Corporation, and the largest domestic manufacturer of aluminum forgings for automotive suspensions. It supplies domestic and transplant automakers across North America.

Kobe Steel anticipates an increasing U.S. market demand for its lightweight components as a consequence of tighter fuel-economy regulations in the coming decade.

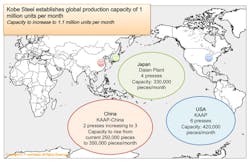

The expansion of the Kentucky operation has been paralleled by Kobe Steel’s expansion of a comparable joint-venture operation in China. Kobe Aluminum Automotive Products (China) Co. Ltd. was launched in 2010 and later expanded with a second forging press. It now produces 1.5 million forged components per year.

With the U.S., China, and the original KAAP forging operation at Daian, Japan, Kobe now has a global capacity of 12 million forged aluminum suspension parts per year.

That volume is due to increase again with a third forging press starting up at KAAP China next fall. Kobe Steel indicated that expansion was decided in March and is in progress now, an investment estimated at $19.3 million (¥2 billion.) KAAP China’s capacity will increase from 3 million to 4.2 million forged parts per year, and the group’s total production capacity will rise to 13.2 million forged suspension parts per year.