RTI International Metals Inc. — a manufacturer of engineered parts for commercial aerospace, defense contractors, energy systems, medical devices, and other applications — has acquired Texas-based Directed Manufacturing Inc., a producer of 3D printed parts in metals and plastics, for commercial customers and engineering development projects.

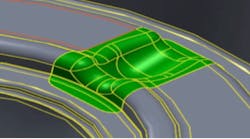

RTI completed the purchase for $23 million, in cash. Directed Manufacturing will be operated as RTI Directed Manufacturing Inc., the group’s foothold in the emerging additive manufacturing sector. It will complement RTI’s other business units with its series of parts in titanium, nickel-chromium alloys and other specialty metals and composite plastics, produced by the direct metal laser sintering (DMLS), selective metal laser sintering, and plastic (selective) laser sintering (SLS) processes.

Its products include aerospace airfoils, rakes, guide vanes and injection nozzles, complex fasteners, surgical tools, medical implants, and injection mold inserts, among others. Its customers include aerospace OEMs and their suppliers

"We believe its (Directed Manufacturing’s) technology, track record of profitable commercial production, proven quality, performance and base of established customers immediately puts RTI at the forefront of additive manufacturing and 3D printing -- the technology that is rapidly expanding it's influence on global manufacturing," stated Dawne S. Hickton, RTI vice chair, president and CEO.

RTI is generally understood as an integrated producer of titanium products — including fabricated products (assemblies, machined parts), mill products (forgings, among several others), and semi-finished materials (bars, blooms ingots, pipes, plate.)

It stated that the Directed Manufacturing acquisition builds a two-year-plus strategy of R&D and other participation in additive manufacturing programs, including collaboration with a commercial aerospace OEM on prototype powder metal parts.

RTI is also a founding sponsor of the National Additive Manufacturing Innovation Institute (NAMII, or "America Makes".)

"The growth potential for Additive Manufacturing solutions in RTI's and Directed Manufacturing's markets is truly exceptional. We look forward to maximizing the commercial opportunities that the new capabilities of our latest acquisition will generate, particularly on the most advanced new commercial aircraft and engine platforms, as well as medical device applications," Ms. Hickton added. "We are also anxious to pursue opportunities with businesses in other market segments that are seeking the cost effectiveness of near-net-shape production that Directed Manufacturing's 3D Printing capability delivers."