Software developer Simufact Engineering GmbH and process equipment manufacturer Schuler SMG GmbH & Co. KG formed a technology partnership recently, aiming to adapt Simufact’s simulation programs for use with hydraulic machines developed by Schuler SMG. Forging companies in particular will benefit, they report, because their alliance will allow customers to simulate entire process chains on Schuler machinery.

The partnership was confirmed recently during the INFORMlive event that Schuler organized in Waghäusel, Germany.

Schuler SMG is Schuler Group’s business unit for hydraulic press systems, which it supplies to customers producing automotive components and other parts for industrial products and appliances. Its product line includes hydraulic forming presses for sheet metal, hydroforming for tubular products, and fine blanking systems.

More specifically, Schuler designs hydraulic cold forging presses, ring-forming lines, and aluminum wheel presses, and it develops turnkey equipment like production lines for railway wheels. It develops open-die forging presses in co-operation with Wepuko/Pahnke.

Now, buyers of Schuler SMG forming machines will be offered a process-specific, integrated software platform they can use to “map and optimize the holistic manufacturing process in their computer,” according to the partners’ announcement.

“To do this, the Simufact simulation software will be adjusted to the Schuler SMG machines to simulate multi-stage forming processes within the process chain with a maximum accuracy,” the statement continued. Integrating other functions of the process will establish “seamless communication between the machine control system, the overall production line control system, and process planning.”

“With Simufact we have a strong partner in the area of process simulation for complex forming processes,” stated Schuler SMG managing director Arnd Kulaczewski. “The integrated and tailored Simufact simulation environment will help our customers to exploit the capabilities of their Schuler machines even more.”

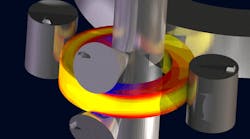

Simufact develops software for manufacturing process simulation, in particular for metal forming processes, like forging, cold massive forming, rolling, sheet metal forming, mechanical joining, heat treatment, and welding. It also customizes manufacturing processes using CAE tools, and offers consulting, training, and technical support.

The developer noted that simulating manufacturing processes “opens up new ways to optimize forming strategies and tooling geometries.

“The required development time for new components will be notably shortened and the process safety will increase. This leads to an optimal use of resources and lower component costs,” Simufact stated.

“The partnership with Schuler SMG opens a high innovation potential,” according to CEO Michael Wohlmuth. “To optimize advanced manufacturing processes it is important to integrate the entire process chain – the combination of multi-stage production lines and software based simulation is the best way to increase quality and efficiency.”