There was a time when the mention of a jib crane installation of any capacity conjured up images of long consultations with architects and structural engineers, even before ripping up the floor, digging foundations, and installing the product.

Those days are gone—but let’s find out why.

What is a Foundationless Jib Crane?

First, let’s remind ourselves what we mean when we say jib crane. In simple terms, it's a type of overhead lifting device, commonly seen in a small workstation area for repetitive and sometimes unique lifting tasks. They are versatile and can even be used in tandem with overhead bridge cranes to accelerate production or make it more efficient.

They are popular in many production environments because they can increase worker productivity, reduce workplace injuries, and improve safety.

Jib cranes are simple in terms of design and are easy to maintain. However, they range greatly in capacity—from, say, 250 pounds up to over 15 tons—and vary in type. You might have heard of freestanding jib cranes, arguably the most common type of jib system, which are base plate-mounted, foundation/insert-mounted or sleeve insert-mounted.

It’s probably fair to say that freestanding systems offer the highest capacities, spans, and height under boom (we call it HUB in the industry), but foundationless is undoubtedly the new buzzword in this sector. And for good reason.

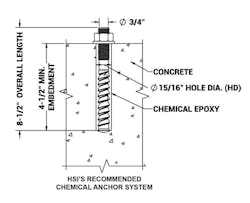

Foundationless jibs are a type of freestanding jib, but they don’t require a special poured foundation. More than that, they can be installed almost anywhere in a workplace that conforms to a manufacturer’s guidance. There’s no need to worry about the 3 or 4-foot deep reinforced foundations that are nearly always required with alternative solutions. Foundationless jibs are different in that they have a larger diameter base plate and additional "upright material", as one distributor put it to me recently—to help relocate the forces.

It's necessary to emphasize that foundationless jib cranes are generally reserved for a lower capacity. For example, Caldwell-branded models are available in ½-ton and 1-ton capacities only. The ½-ton version has a maximum span of 20 feet and a HUB (remember, that’s height under boom) of 20 feet while the 1-ton version has a maximum span of 16 feet and a maximum HUB of 16 feet.

You can only imagine the breadth of application this suits them too, without ever having to dig deep foundations and make a crane a permanent fixture within your facility.

That’s a point worth reiterating, because the production flow of a warehouse, production or manufacturing facility varies greatly, even from week to week. It might be that a crane is only required in a certain place at a specific capacity for a period of time. If the 3 or 4-foot deep reinforced foundations we’ve spoken about house the jib crane, it’s not a tool that can be easily removed, and certainly not worth relocating if its new workstation might turn out to be just as temporary.

Looking for crane solutions? Check out the NED Directory for the latest cranes on the market.

A Turnkey Solution

Another reason why foundationless jib cranes are becoming more popular is that they now come with a much more comprehensive turnkey package, with all components included in the price of the crane. There’s no longer a need to go out and shop for the parts separately, particularly if you’re working with a reputable manufacturer or distributors/dealers.

Caldwell is a great example of this; Contact a Caldwell partner and they can get you a foundationless jib crane, tagline kit, special anchoring bolts, two-part epoxy, and even an epoxy gun. Your supplier should be able to do the same too.

Partnerships between the manufacturer, dealer, and end-user build great trust too. If a Caldwell product, like a foundationless jib, is provided by the Grainger platform, for example, the user isn’t concerned about the lack of reinforced foundations because they know the solution has been designed, engineered, and sold by the leading authorities in the land. Further, it’s backed up by people that know more about jib cranes than anybody else.

In Foundationless Conclusion

So, it’s clear why foundationless jib cranes are proving their worth in the 1-ton capacity range across a myriad of sectors. Generally, I've monitored increased uptake through single-crane orders, which isn’t a surprise given the capacity and application situations we’ve spoken about, but there have had orders where a customer will be outfitting a new plant or new portion of a facility and these solutions emerge at the top of their material handling order list. That said, the marketplace will remain for low-unit, commodity, quick shipment-style acquisitions.

Remember, traditional and mast-type jib cranes will always have their place. There are many applications in an industry where a 1-ton capacity, a maximum span of 16 feet, and a maximum HUB of 16 feet, just won’t do the job. And that won't change.

What we’re recognizing, though, is that purchasing decision-makers are more readily noting that ripping up the floor, digging foundations, and installing cranes might not be necessary. The same goes for wall or column-mounted jib cranes; a lot of cost and ingenuity often goes into these installations that might be better saved for another facet of a busy operation.

Might your next jib crane purchase be for a foundationless one? Let us know how it works out.