What would you do if your son was born a month early, suffering from severe brain damage and with grim prospects for ever even sitting up by himself?

For Matej Vlašič, of Maribor Slovenia, the answer was anything he could to provide son Nik, born in 2010 and diagnosed with cerebral palsy three years later, the highest quality of life possible.

For that to happen, Nik would need serious physical therapy and ankle foot orthoses (AFO) to condition his weakened joints to support his weight and align his twisted feet, which he was ready for at age 6. The process of obtaining AFOs can exceed $1,000, take months to complete from sizing to fittings to fabrication, and cause discomfort and irritation to the wearer. Several iterations may be required to get the right fit and account for the child’s growth. But they are wholly necessary to get early in the body’s development.

“The lack of comfort and high price combined with all the other cons were enough that I decided to do something about it,” says Vlašič, an engineer with 12 years of experience in telecoms R&D. “I didn't have the solution at that time, but I wanted to find a better way to design it. I was just trying to help my son in the best possible way.”

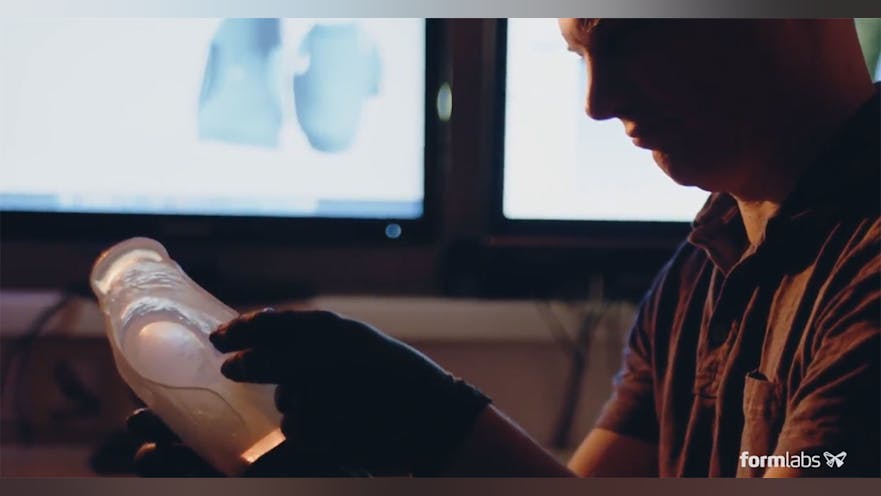

As with several pediatric applications involving orthotics and prosthetics, Vlašič turned to 3D printing. After half a year of research to find the best methods to create the orthoses, fine-tuning a workflow using the Formlabs Form 2 stereolithography (SLA) 3D printer, and 13 prototypes, Nik had the support he needed, which comfortably fit into his normal pair of shoes.

Vlašič says Nik was walking within a few days, and a few months later walking faster, even dancing.

The seven-year-old is on his fourth pair now. With any luck, he may not need a fifth.

In a conventional case, using the 50-year-old orthotics manufacturing technology involving manual measurements and plaster casts, the Vlašičs could be out more than $5,000. A Form 2 costs $3,500. One liter of Durable resin costs $175, and the orthoses are an average of 85 mL, making one pair cost less than $15.

Vlašič started his own company, aNImaKe, to create a way for more families in need to access the technology.

My own daughter, who had trouble standing up, was diagnosed with benign congenital hypotonia at about 16 months and required orthotics that took a few months to get. Luckily, insurance covered the first pair and she’s walking much better now at 2. If she needs a second pair, that could cost several hundred dollars.

More Support

During the development of the orthotics, last May, Vlašič sent an email to Formlabs general contact he found on the website, recounting his struggles and progress, and asking for some technical advice from the manufacturer.

Two months earlier, Formlabs had hired Gaurav Manchanda as director of healthcare to increase the company’s footprint in the medical sector. For Manchanda, a public policy expert who had recently returned from war-torn Liberia, where he was working to bring more renewable energy solutions to power hospitals and medical centers there, receiving this email meant as much to him as Vlašič.

His three-year-old son was born at 25 weeks and weighed less than a pineapple, spending his first four months in the neonatal intensive care unit. He, too, was diagnosed with CP. There are more than 17 million cases worldwide, and the CDC puts the frequency at 3.3 children per 1,000 live births.

Before even getting used to all the canine companions at Formlabs’ dog-friendly Somerville, Mass., office, Manchanda had a gift-wrapped use case that could tackle this global—and very personal—problem while highlighting the strengths of the Form 2.

The Form 2’s high-resolution SLA process uses a laser to cure the part top to bottom from a tray of liquid material. The build volume of 145 x 145 x 175 millimeters, perfect for pediatric orthoses. Scanning and printing can take 24 hours.

Manchanda recommended Vlašič switch from the Tough to Durable print material, which emulates the polypropylene used in traditionally made orthoses, as well as extending the patented workflow for making the supports to the U.S. market. Since then, the two fathers have been in close communication via WhatsApp Messenger, and Formlabs has given materials and other technical advice to the Slovenian engineer.

Formlabs also works with organizations around the world, from research institutes to non-profits, to further the cause.

They also produced this video to highlight the use case for the Form 2, which Manchanda calls a “high accuracy, professional-grade, regulatory-body-validated printer, along with a fairly affordable price point that should open up other markets responsibly.”

Watching the video caused Manchanda and his wife to start “bawling,” as it inspires hope for his three-year-old, who now can only army crawl, but may improve to the point of Nik, who can bike and hike with his family.

“Even if my son doesn't improve from this process, we can still help millions of people around the world if this technology can scale,” Manchanda says. “If we play a part in that, it’s super fulfilling.”