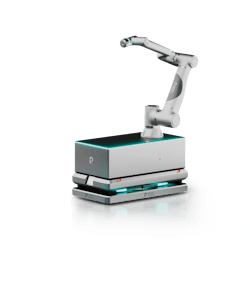

IMTS 2024: Rethink Rise Mobile Manipulator Offers a Solution for Long Cycle Times

Combining its Rethink Ryder AMR with one of its Rethink Reacher cobots and a portable battery box, Rethink Robotics allows mobile manipulation to be performed at new levels of efficiency with the Rethink Riser.

The Rethink Reacher and Rethink Ryder, components of the Rethink Riser, each have their own battery packs, requiring separate charging. The Rethink Reacher offers 22-hours of uptime. The Rethink Ryder can be charged in two ways: manually or wirelessly through inductive charging. Each Ryder AMR comes with three or four battery units based on its size. If higher uptime is required, customers can request up to two additional battery units per Ryder AMR.

The control box that comes with the Reacher cobot is a compact and integrated unit designed to manage and control the robot's operations. It houses the essential electronics, including the robot's processor, power supply, and communication interfaces. It serves as the central hub for executing commands, processing sensor data, and coordinating the robot's movements. The Rethink Riser's control box is added as an attachment onto the Ryder so it can fully move along with it in combination with the Reacher cobot arm.

Rethink Riser is a perfect solution for intermittent pick-and-place operations and machine tending applications where cycle times are relatively long, making it difficult to justify the purchase of a dedicated cobot for each station. Rethink Riser allows flexible cobot redeployment, with each component achieving its maximum ROI potential.

Features:

Rethink Robotics

Boston, MA

[email protected]

rethinkrobotics.com