VibWorks LT Entry-Level Vibration Data Collection

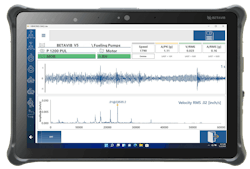

VibWorks LT, an entry-level, portable data collector for industrial maintenance, features advanced AI for real-time data collection and analysis. Enhancing maintenance decision-making with minimal setup and training, its design and customizable reporting ensure comprehensive monitoring and easy documentation.

With intelligent anomaly detection, the system predicts potential issues well before they escalate into costly downtime. Upon detecting an anomaly, the AI suggests the most probable causes and recommends actionable solutions, streamlining the troubleshooting process and saving valuable time and resources.

Generate reports with a single click to document issues and actions, ensure regulatory compliance, and have a historical record. The system's user-friendly interface allows for easy navigation and setting adjustments, making it accessible to users with varying levels of technical expertise.

The architecture ensures that all machines are under proper surveillance with comprehensive machine listings that detail their operational status. This ensures no machine goes unnoticed, providing a clear overview of the entire fleet of assets. The AI module improves its diagnostic accuracy over time by leveraging historical data, making the system more reliable and insightful with each analysis.

VIBEWISE, an integral part of the VibWorks ecosystem, leverages machine learning algorithms to provide predictive maintenance insights. It analyzes historical and real-time data to forecast potential equipment failures, offering actionable recommendations to optimize maintenance schedules and improve overall machinery reliability.

Overall, the VibWorks LT portable vibration data collector offers a budget-friendly solution for high-quality data acquisition and vibration analysis, helping industries stay ahead of potential machinery failures and optimizing maintenance practices effectively.

Features:

- Route-Based Interface easily tracks route progress, manages out-of-service machines, and locates unfinished equipment repairs within a route with one click

- Smoothly navigate to any machine for efficient data collection

- Benefit from AI machine learning algorithms for anomaly detection, actionable insights, and maintenance recommendations, including lubrication schedules and bearing replacements

- Generate reports with a single click for documentation and regulatory compliance

Price: Contact the company for a quote or to get an on-site demo

| Certifications | MIL-STD 810H, MIL-STD 461G |

| AC Adapter | AC adapter: 100 to 240V, 50 to 60 Hz, 65W |

| Main Battery | Li-ion, 7.6V, 3600 mAH, 8.5 hr |

| Operating Temp. | -4 to 140°F (-20 to 60°C) |

| Dimensions (W x D x H) | 9 x 6 x 1 in. |

| Weight | 2 lb. (1 kg) |

| Battery | 17 hr runtime |

| Display | 8 in. LCD (1280 x 800) |

| Graphics | Intel Iris Xe graphics |

| FMAX | 20 to 40 kHz |

| Range | ± 100g PEAK @ 24 bits |

| Resolution | 200 to 208,400 lines |

| Window Functions | 14 embedded window types |

| Numbers & Averages | Up to 10,240 |

LUDECA, INC.

Doral, FL

(305) 591-8935

[email protected]

ludeca.com