VERYX BioPrint Digital Sorter

The first VERYX BioPrint digital sorter is the world’s only sorter that can combine near-infrared (NIR) hyperspectral detection with color cameras. VERYX BioPrint analyzes a richer set of data about the materials it is sorting to improve detection performance and maximize process yield. Key’s VERYX BioPrint C140 sorter for nuts removes shells, foreign material (FM) and product defects as well as shape sorts and color grades to maximize product quality while virtually eliminating false rejects.

Sorting walnuts, almonds, pistachios, cashews, and other nuts, VERYX BioPrint removes shells, rocks, sticks, glass, plastics, moisture-related defects, insect and other surface damage, rot, mold, and more while color grading and shape sorting to meet even the most stringent product quality specifications.

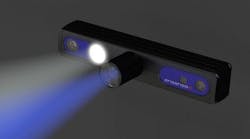

VERYX BioPrint C140 can be equipped with front- and rear-mounted hyperspectral imaging sensors for all-sided inspection of each object in the product stream. It can be configured with color cameras and Key’s new Bio Fusion detection technology, which uses information from both sensor types to uniquely identify and remove a wide range of foreign materials and defects from the product stream.

Hyperspectral imaging utilizes many more wavelengths of information than other NIR inspection systems to detect the chemometric and biological properties of objects. Multi-channel, high-resolution color cameras facilitate precise color grading and shape sorting. Bio Fusion combines pixel-level data from the hyperspectral sensors and color cameras to produce a unique ‘signature’ associated with each material substance that passes through the sorter. This enables VERYX to identify and remove the most difficult-to-detect FM and defects, without the yield loss generated by inadvertently directing good product to the reject stream, even when defect loads are very high.

Sorting up to 8 metric tons of product per hour, VERYX BioPrint C140 is a versatile solution for sorting nuts from pre-selection to final grading. It works perfectly as a stand-alone sorter, either inline or batch-fed, and in a cascading line of multiple sorters, depending on the needs of the processor.