Sapphire XC, an “Extra Capacity” large-format printer, will increase production throughput by 5X and reduce cost-per-part by up to 75% when compared to the existing Sapphire system.

The company also announced plans to roll-out Sapphire Gen 2, which will be a software and hardware upgrade to the current system. Users can expect an improvement of anywhere between 10 to 50% in productivity and part-cost metrics when compared to the current Sapphire system. The Sapphire Gen 2 upgrade will be available to retrofit on all installed systems starting in Q2 2021.

The Sapphire product family now includes Sapphire Gen 2, the 1-m tall Sapphire 1MZ, and Sapphire XC—all using the laser powder-bed fusion (LPBF) process with patented capabilities to print without consideration of support structures. Sapphire systems specifically address the aerospace, power generation, and energy markets' unmet needs for quality-assured manufacturing of uncompromised geometries.

Sapphire XC Pre-Order

Delivery of Sapphire XC will begin in Q4 2021. Early pre-order of Sapphire XC secures a price and an early manufacturing slot for the system. Existing orders of Sapphire XC will consume all available manufacturing slots for Q4 ’21 and most of Q1 ’22.

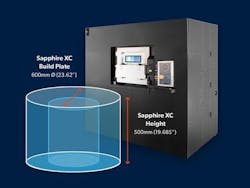

- Larger build volume: Build volume 600 x 550 mm (compared to 315 x 400 mm in Sapphire)

- Higher productivity for production: 8 lasers x 1,000W each (compared to 2 lasers x 1,000W in Sapphire)

- Integrated manufacturing process: Fully integrated with Flow pre-print software and Assure quality control software

- Consistent architecture: Utilizes the same optical-train design, recoater technology, gas-flow technology, and metrology as the current Sapphire. Users can also expect similar material properties as Sapphire

- Qualified material alloys: Compatible alloys include Aluminum F357, Titanium 6AI-4V, INCONEL 718, and HASTELLOY X