Digital manufacturing innovator VELO3D announced the commercial release of a manufacturing process for additively manufactured parts in Aluminum F357 on the company’s Sapphire metal 3D printing system.

The foundry-grade aluminum alloy, suitable for the laser powder-bed fusion (LPBF) process, enables 3D printing of parts that have traditionally been manufactured using casting practices. There are other Aluminum alloys that are more commonly used in metal additive manufacturing, such as AlSi10Mg, but Aluminum F357 can be anodized and shares characteristics with A356, a widely used casting alloy.

“Aluminum F357 has already been certified for mission-critical applications—unlike some exotic alloys—so it was a logical addition to our materials portfolio,” states Benny Buller, Founder and CEO of VELO3D. “We will continue to add more compatible materials that enable customers to print parts they couldn’t before, yet with even better material properties than traditional manufacturing.”

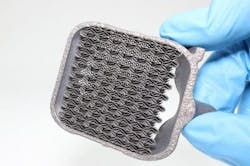

The manufacturing process of Aluminum F357 for Sapphire was developed jointly with PWR, a global supplier of advanced cooling solutions to Formula 1, NASCAR, and other racing series, along with automotive, military, and aerospace industries. “We chose Aluminum F357 due to its ideal material properties to suit thermal performance, machining, and weldability,” states Matthew Bryson, General Manager for PWR.

“Our ability to print free-form and lightweight structures for heat transfer applications with our Sapphire system from VELO3D will further enhance performance and packaging optimization opportunities for our product range and provide significant value to our customers.”

VELO3D is known for enabling geometric freedom through its patented SupportFree process, which eliminates the consideration of support structures for complex passageways, steep overhangs, and low angles. Coupled with its non-contact recoater, its printing process can produce the ultra-thin wall structures and high aspect ratios that are essential for a variety of flight-critical applications.