Simulation Helps Aerospace Industry Meet Growing Demand

NCSIMUL MACHINE simulation and optimization software helps aerospace and other manufacturers create “digital twin” process models that facilitate fulfillment of customer demands for higher production rates and unwavering product quality.

Aerospace industry analysts say aircraft production will continue to grow for two decades or more; the worldwide civil aviation fleet alone is expected to double. To meet the continual ramp-up in aircraft output, OEMs and subcontractors alike are employing leading-edge machine tools, tooling and CAM software in the Internet of Things (IoT) / Industry 4.0 environment.

A key element of the Industry 4.0 domain is the creation of electronic “digital twin” models of product data and production processes. The virtual models correspond with the physical shop floor processes and allow manufacturing operations to be simulated, tested and altered to avert possible problems and downtime and while also facilitating process optimization. Such cyber-physical systems bridge the gap between the real and virtual worlds.

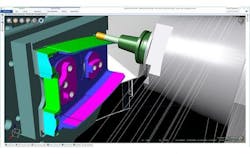

NCSIMUL MACHINE software works directly with ISO NC machining codes to simulate, verify and optimize machining programs based on specific parts, tooling, and machine tool characteristics. Three-dimensional graphics help prevent crashes while complex algorithms and embedded process-based knowledge enable optimization of cutting conditions. Use of the software reduces time spent debugging programs, eliminates the risk of spindle collision, tool breakage, and scrap, and improves cycle times, process efficiencies, and machine utilization.

NCSIMUL MACHINE provides machining verification in three steps: it investigates and corrects coding errors, simulates to detect collisions and correct motion errors, and validates the machining results. The software also monitors production transfers, tool management, and machine status. Overall, use of NCSIMUL software can help manufacturers meet delivery schedules, maintain aerospace-level product quality and reduce preparation times up to 70% while cutting costs by 20%.

Silvère Proisy, SPRING Technologies North American operations manager, said, “NCSIMUL MACHINE enables manufacturers to increase the flexibility, speed and profitability of their operations by achieving complete and integrated mastery of Industry 4.0 manufacturing processes.”