How an Ultrasonic Sensor Helps Produce the World's Finest Cheeses

Americans love their cheese: the average American consumes over 34 pounds of cheese per capita.i The U.S. is also a surprisingly large producer of cheeses. Wisconsin alone produces over 3.2 billion pounds of cheese each year in this multi-billion-dollar industry.ii

Creameries and cheese makers still follow many of the ageold traditions that our ancestors pioneered. They will use an ingredient like rennet to cause proteins in milk to coagulate into curds, from which a mind-boggling variety of cheeses can be produced.

But, to craft truly best-in-class cheeses, modern cheese makers must use world-class equipment.

Since its founding in 1947, Alpenland Maschinenbau GmbH (ALPMA) has developed into one of the world's leading manufacturers of machines and systems for the cheese and food industry.

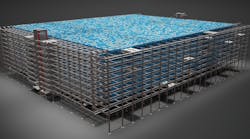

Among their many diverse innovations, ALPMA developed a coagulator that allows for the continuous production of curd (see image) – a major milestone in cheese making. Prior to its invention by ALPMA in 1976, the curd was produced in batch processes. Today, with ALPMA, high quality cheeses can be produced in volumes previously thought impossible.

And true to their reputation as a leader in the dairy and cheese making industry globally, the ALPMA coagulator uses only the best materials and components, including the P53 ultrasonic sensor to measure the level in the coagulator. The EHEDG-certified P53 sensor enable efficient cleaning, less wear over time, and lower costs due to its hygienic design and fully encapsulated stainless steel.

How the coagulator works.

The coagulator designed by ALPMA consists of a stainlesssteel trough, up to 262 feet long, equipped with a specific belt and an ingenious partition wall system. Thereby cells are created in which milk and rennet are continuously supplied while the curd is continuously removed at the other end.

That means the ALPMA coagulator can produce curd nonstop. The ALPMA 2000 coagulator, for instance, can process nearly 12,000 gallons of milk hourly. That enables creameries to scale production to previously impossible levels – and yet still produce cheeses with the same quality and flavor as though they were making small batches.

Many creameries and cheese makers worldwide rely on ALPMA machines; for example, the majority of the American production of White Cheese / Feta and Cagliata (base product for mozzarella and pizza cheese) is manufactured using ALPMA equipment.

Safe, high quality cheese making depends on hygienic conditions and equipment.

Any equipment used in food production, including cheese making, must meet the highest standards of hygienic design; food safety and quality depend on it.

That’s why ALPMA now uses the hygienic ultrasonic sensors of the P53 series from PlL for level detection in the coagulator.

The coagulator and its component parts must endure frequent, thorough cleaning using highly acidic and/or alkaline cleaners – yet also keep cleaning efforts and plant downtimes as short as possible.

The detergents used in food production can penetrate even the smallest nooks and crannies to effectively remove any contamination and thus prevent bacteria from taking root and spreading. Often, these cleaning operations can lead to rapid wear, damage, and premature breakdown.

However, the P53 offers all-around stainless-steel casing and chemical-resistant seals that can withstand the rigorous cleaning protocols involved.

So too can it withstand steam, moisture, and the properties of objects and surfaces – none of which can interfere with the P53’s precise distance measurement.

How do ultrasonic sensors work?

Ultrasonic sensors use high-frequency sound waves to detect the position and distance of objects – including those whose surface structure, material, or color might distort readings for other sensors and equipment.

How does the P53 work?

The P53 sensor is fully encapsulated in edgeless stainless-steel housing (rated up to IP68/IP69K, so it’s easy to clean even with harsh chemicals. It’s robust against dust, moisture, steam, and high temperatures.

The P53’s design and specs fit the needs of food production facilities perfectly.

Very few sensor manufacturers offer sensors or accessories in hygienic EHEDG-compliant designs, due to the high costs of certified hygienic development.

For this reason, many manufacturers of hygienic-critical applications rely on conventional sensors that require special cleaning considerations and are prone to increased cleaning costs and premature wear to comply with hygiene requirements.

Thanks to a high degree of protection (meeting lP68 and IP69K ratings), a fully encapsulated gapfree design made of V4A steel, and an allowable temperature range from -15° to 80°C (5° to 176°F), the P53 sensors can be easily cleaned with high-pressure or steam jet cleaners as production facilities wash their machines normally.

The seamless transition of the casing into the front metal-sound membrane and the smoothness of the polished surfaces offer no adhesion for germs and thus guarantee maximum hygiene.

Further, added aggressive cleaning agents are no problem for the sensor casing, whose chemical resistance is certified according to ECOLAB. In terms of robustness and insensitivity to a wide range of interfering factors, no other sensor is more suited for use in the food industry than the P53, even for delicate food production processes like cheese making.

Quick assembly with the EHEGD-compliant mount.

The P53 sensors come in variants with 30-mm or 18-mm casing diameters for measurement ranges of 80 up to 1,500 mm. The versions with analogue output (4..20 mA) are supplied by PlL with fixed characteristic curves, while the desired switching point for models with switching output via teach-in can be set quickly and easily by the user.

In addition, PIL is one of the few manufacturers to offer an EHEDGcertified holder for their hygienic sensors for reliable mounting or fixing in wall bares and casing openings or holding devices.

The holder consists of two halfshells which can be screwed together, and each have a passage for one of the sensor ends.

When the halves are screwed together, the transmission seals made of foodstuff-resistant silicone 70/101, which meet the FDA’s approval requirements, are firmly pressed onto the conical shaped sensor ends and seal the gap between the sensor and the holder completely, reliably, and hygienically.

Even better, the application possibilities range much farther than just level measurement, including also counting containers, band control, and/or monitoring the correct fit of enclosures.

With its use in ALPMA’s coagulator, the P53 ultrasonic sensor proves itself as a reliable and economical part of producing some of the world’s finest foods.