Advantages of Asymmetric Membranes

Because they have similar outward appearance, it is easy to presume that the various microporous membrane filters and flat sheet membrane filters offered by Sterlitech have similar pore structures. Some consider symmetry to be the epitome of beauty, but with respect to filtration, it’s all relative. In reality, there is a rich variety of pore structure morphologies resulting from the techniques and materials used to manufacture the membranes.

For the microporous membrane filters, the pore structures range from the essentially two-dimensional screen-like structures of the polycarbonate and polyester track-etch membranes, to the node and tendril structures of the expanded PTFE membranes, to the entangled nanofiber structure of the polyacrylonitrile (PAN) membrane, and to the convoluted lacey foam-like structures of the solvent cast membranes such as cellulose acetate (CA).

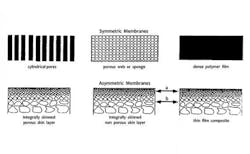

Some solvent cast microporous membranes, such as Nylon, have essentially symmetric pore structures where the voids are similar in size throughout the thickness of the membrane. While others, such as mixed cellulose esters (MCE) and polyethersulfone (PES), have asymmetric pore structures where the voids are smallest near one surface and largest on the opposite surface. And still others, such as polypropylene (PP), have anisotropic pore structures where the smallest voids occur within the membrane away from either surface. Finally, is it possible for anisotropic membranes to also be symmetric or asymmetric. These seemingly subtle differences in pore structures actually have substantial influence on membrane performance.

The flat sheet membrane filters also have a variety of pore structures. Cellulose Acetate (CA) reverse osmosis and nanofiltration membranes tend to have dense symmetric pore structures. While thin film composite (TFC) reverse osmosis and nanofiltration membranes have an asymmetric pore structure polysulfone layer with the largest pores on the permeate side and a very thin dense coating of crosslinked polyamide on the feed side. Similarly, ultrafiltration membranes typically have asymmetric pore structures with the largest openings on the permeate side and a dense “skinned” surface on the feed side.

The asymmetric microporous membranes and the asymmetric flat sheet membranes tend to have superior performance when compared to their symmetric counterparts. However, they are asymmetric for different reasons. The asymmetric microporous membranes are ideally not skinned and they are operated with the largest pores facing upstream. The larger pores act as a prefilter to the smaller pores on the opposite side; they stop larger particles at the surface but purposefully allow smaller particles to enter the pore structure. This helps prevent surface blinding of the membrane and actually improves throughput. This orientation is exactly opposite of the asymmetric flat sheet membranes. These membranes are ideally skinned and are operated with the smallest pores facing the feed. The smooth skinned surface faces upstream so that particles do not enter the pore structure, but are instead swept away by cross flow. The flat sheet membranes are asymmetric by design to improve permeate flux by reducing flow resistance.

Lastly, proper orientation of asymmetric membrane filters is critical for optimal performance. For the flat sheet membranes, the filters must be oriented so that the smooth membrane surface is facing the feed. Almost all flat sheet membranes have a strong nonwoven support layer on the permeate side. With minimal amounts of experience, most users become adept at identifying the surfaces and observing proper filter orientation.

Some consider symmetry to be the epitome of beauty, but now we know better. For the microporous membranes, the filters should be oriented so that the surface with the largest pores is facing upstream. Typically, the surface with the largest pores is matte or dull while the opposite surface with the smallest pores is shiny.