Improved Software Minimizes Machining Times

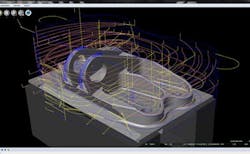

Optimization capabilities of the NCSIMUL package have been enhanced to minimize air-cutting motions and machining times. The improvements are contained in the NCSIMUL OPTITOOL module of NCSIMUL MACHINE, the CNC machine verification software for simulating, verifying, optimizing, and reviewing machining programs.

Capabilities now include algorithms that transform working feed rates into rapid feed rates or specified maximum feed rates for approach and retract motions in both circular and linear toolpaths. The software’s Air Cutting Optimization mode can enable users to reduce machining times by 4 – 25%, which results in immediate savings on every part produced.

Simple, one-click implementation requires no alteration to the toolpath or CAM system. The software is effective in Fanuc, Heidenhain, Siemens and any other standard CNC control languages. NCISMUL OPTITOOL also enables users to test different optimization strategies and provides graphic analysis comparing initial and optimized feed rates. Further, this optimization can be repeated on every machined part currently in process, multiplying the gains.

NCSIMUL MACHINE is an innovative CNC software solution providing realistic CNC simulation of the machining process. Users can simulate, verify, optimize and review machine programs based on the actual characteristics of the machine tools. Three-dimensional graphics help to avoid machining crashes while powerful algorithms and embedded process-based knowledge enable cutting conditions to be optimized. NCSIMUL MACHINE provides machining verification in three steps: it investigates and corrects coding errors, simulates to locate collisions and correct motion errors, and validates the part cut and machining result.