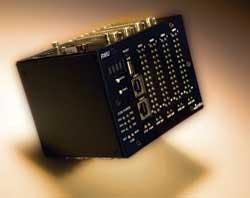

Open Control Platform for Industrial Automation

MKS Instruments, Inc., a leading provider of process control technologies for improving productivity in semiconductor and other advanced manufacturing processes, has introduced the CONTROLweb™ Open Control Platform for industrial automation applications. The CONTROLweb™ platform uses an Ethernet backbone to enable modular, idealized control architectures. The suite of configurable modules, including RMU Linux Logic Controllers and MicroNode™ and MacroNode™ intelligent Ethernet I/O units, maximizes logic flexibility and I/O performance while minimizing deployment and support costs. The RMU controller provides a ready-to-program, high density computing platform with built-in I/O and peripherals. It features 32-bit PowerPC™ technology, Linux OS, dual Ethernet ports, USB, serial and CAN ports, and customer selectable configurations of up to 96 digital I/O and up to 32/16 analog I/O channels. Control logic and application flexibility is based on C/C++ running on Linux and is limitless compared to traditional PLC systems. The CONTROLweb MicroNode and MacroNode Ethernet I/O modules further extend logic flexibility with the cLogic™ control engine. The cLogic software enables customers to embed custom logic within these Ethernet I/O modules, providing real-time intelligent responses to remote critical signals. Using standard TCP/IP protocols, these modules provide high density, remote I/O with response times down to 2 msec. 37-pin D-Sub connectors in the MicroNode and MacroNode units provide easy I/O connections. Linked with an RMU, these units distribute and optimize I/O performance across an industrial control system network. Built-in web browser diagnostics make the CONTROLweb platform easy to deploy and support. Custom modules which meet exact customer requirements are available upon request. About MKS MKS Instruments is a leading worldwide provider of process control solutions for advanced manufacturing processes such as semiconductor device manufacturing and thin-film manufacturing for flat panel displays, optical storage media, architectural glass and electro-optical products. We also provide technology for biopharmaceutical and medical imaging equipment. Our instruments, components and subsystems incorporate sophisticated technologies to power, measure, control and monitor increasingly complex gas-related semiconductor manufacturing processes, thereby enhancing our customers' uptime, yield and throughput, and improving their productivity and return on invested capital.