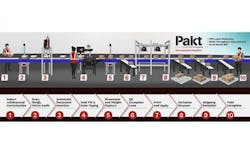

Pakt All-in-One Pack & Ship Automation Line

Pakt, an all-in-one modular, scalable, post-pick, end-of-line, pack-and-ship solution automates the final 100 ft of a DC’s order fulfillment operation. The system includes predeveloped modules that streamline labor and eliminate fulfillment bottlenecks in the pack-and-ship operation.

Pakt is designed for warehouses that depend on people performing manual packing and manifesting tasks such as tote-based picking, order packing, keystrokes, hand weighing, and hand applying shipping labels & packing slip documentation.

By automating these tasks, Pakt saves an operation $350k of labor per shift for every ten manual workers in packing + shipping. These savings translate into a 12 to 18-month ROI for single-shift operations and a 6 to 9-month ROI for two-shift operations.

The automation line can accommodate operations of all sizes. Operating in a small footprint, it provides ~500% throughput improvements and has the capacity to scale up to 1,800 cartons/hr. Ideal for warehouses shipping 800 to 20,000+ pre-packed cartons and full case parcels daily, it's inherently designed with scale in mind with the below modules:

- Induct with advanced Cartonization: Pakt’s cartonization logic goes far beyond liquid fill logic, enabling customers to achieve over 90% cube utilization.

- Scan, Weigh, Vision Audit: To ensure the right products have been picked into the correct shipping container based on weight and to provide image-based traceability via cameras.

- Automatic Document Insertion: Print, fold, insert (PFI)/Document insertion: To automatically insert any packing slips, marketing materials or compliance documentation.

- Void Fill & Auto-taping: To have rules-based, system-directed void insertion as well as automatic taping of the shipping container.

- Dimension and Weight Capture: To calculate an accurate dimensional weight of a carton to properly rate shop and to avoid carrier chargebacks.

- QC Exception Lane: For cartons that are outside of the expected weight threshold to be diverted to an exception lane for further quality control.

- Print and Apply: To automatically manifest, print, and apply shipping labels without any manual touches.

- Sortation Scanner: To scan the box after the label application to accurately sort to the destination location.

- Shipping Sortation: To automatically divert shipping containers based on parcel carriers, LTL, and FTL designations.

- Pakt Complete: Rest easy knowing your orders have been shipped in time for carrier cut-off.