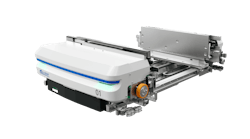

AURORA™ DUAL ROTOR CRUSHER PRODUCES A HIGHER THROUGHPUT, SMALL PARTICLES

Nov. 18, 2006

Related To: Stedman Machine Co

The Aurora™ Dual Rotor Crusher by Stedman, is the ideal solution when delumping for pneumatic conveying or unloading. The dual shaft design produces a higher throughput and small particles, making the Aurora Dual Rotor Crusher best suited for delumping filter cake, frozen vegetables, phenolic resin blocks, rework candy, salt or crystalline material, dryer discharge material, dryer feed material, detergents and soap, rendered products, and solid waste products.The combs on the Aurora Dual Rotor crusher are machined out of solid block of metal for additional strength. The Taper-Lock Shaft Mounted Reducer eliminates gearbox wobble when operating and Double End Wall construction helps protect seals and bearings by preventing blowouts. The Screen-In-A-Drawer makes maintenance easy.The Aurora Dual Rotor Crusher is built with high strength carbon steel, sanitary 304 stainless steel or other alloys available to meet your requirements. The Aurora Dual Rotor Crusher has several available tooth styles, and individual teeth can be easily and economically replaced onto a single key shaft.Customers can test their material in a full-size Aurora Crusher. Stedman has one of the finest testing facilities in the business, with over 163 years of experience. Customers can provide Stedman with 200-300 lbs. of feed material for a full-size equipment test or Stedman can draw from the many test reports already on file for a variety of materials. The objective of the Stedman test center is to help customers choose the right equipment for the job.Stedman, the originator of the cage mill, is the expert in the science of size reduction, allowing customers to test before they buy in Stedman's full-scale test plant. Stedman's full range of equipment includes impactors, hammer mills, cage mills, crushers and lumpbreakers and fine grinders.