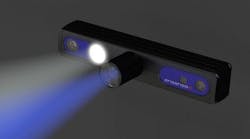

An innovative conveyor system that features an all new Gradient Cooler which provides cooling of hot items as they are transported along the line is being introduced by SmartMove Conveyors of Fall River, Massachusetts. SmartMove’s compact Gradient Cooler houses a tangential blower that can easily mount onto new or existing SmartMove conveyors. The unit provides 130 cubic feet per minute (cfm) of ambient airflow parallel to the belt travel for superior stress relieved cooling. Hot items are moved toward the cooling unit where they are bathed in a stream of air that gradually cools them to room temperature. The Gradient Cooler provides controlled cooling by funneling ambient air in the opposite direction of the products to produce a steady convective cooling curve. Air moves from coolest to hottest items in an enclosed hood assembly. “Other companies use cross cooling methods that can create hot and cold zones that allow component surfaces to cycle from cooling to core reheating,” says VP Gregory Ferguson of SmartMove Conveyor. “These uncontrolled cycles can induce stresses that may distort materials leading to product malfunctions.” Benefits of the Gradient Cooler include: consistent gradual cooling; simple setup; versatile mounting – the cooler can be mounted anywhere along the conveyor length, and low power consumption. Suitable for applications that include wave solder, pad printing, shrink wrapping, UV curing, injection molding, and food processing. SmartMove Gradient Coolers are available for SmartMove Conveyors with belt widths from 12” – 24”.