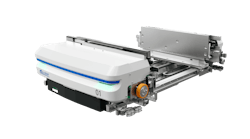

Restore commodity flow and regain storage capacity with the new Aerated Bin Bottom by Cyclonaire Corporation. The Aerated Bin Bottom bin discharger provides safe and efficient unloading of fluidizable material from silos, bins, and surge hoppers, while using low-pressure blower air to bring about smooth flow of any commodity and provide total bin aeration. When dry bulk material rat holes or bridges in the storage facility, or clings to the silo walls – preventing total unloading – the Aerated Bin Bottom offers a cost-effective, simple solution to get the material flowing and keep it moving. The innovative design ensures the continuous flow of fluidizable bulk granular materials finer than 80 mesh. The Aerated Bin Bottom and a minimum 8º internal slope rely on gravity and air and a center discharge to allow positive flow and clean out. The result is a more effective, smoother material discharge and shorter discharge time. The carbon steel-built unit can be installed on new or existing storage facilities, and custom constructed to account for limited-access areas and specialized applications. Each bin discharger comes with a specific low-pressure Cyclonaire Blower Package, based on the customer’s requirements for elevation, temperature, noise reduction, and Bin Bottom size. Blower packages come standard with a high-quality inlet filter with service indicator, premium inlet and exhaust silencers, full flow safety pressure relief valve, and heavy-duty outlet check valve. Each Aerated Bin Bottom is easy to operate and maintain. All mechanical components are installed outside of the storage unit for ease of service and added safety. No hazardous confined space entry is necessary. Each bin discharger is made up of four plenums, that are under a slight positive pressure and feed air through the media to fluidize the material. The quadrants fluidize material independently to prevent the entire Aerated Bin Bottom from going offline should one section experience a problem. Operation continues until maintenance can be performed. Cyclonaire’s Aerated Bin Bottom unloads even the smallest amounts of product that gravity only or other types of bin dischargers might leave behind. Because it has no moving parts and requires very little power, the Aerated Bin Bottom is safer than vibrating bin dischargers and it can unload in a matter of minutes. Cyclonaire offers the Aerated Bin Bottom in custom discharge configurations and in sizes from 2 feet in diameter to up to 16 feet in diameter. Cyclonaire is a manufacturer of bulk material handling systems and controls, specializing in pneumatic conveying. The company supplies components as well as complete dilute, dense, and semi-dense phase conveying systems. Its services range from concept engineering and project management through start-up supervision. Industries served include cement, chemical, battery, food, foundry, milling, mineral, railroad, and rubber.