MX7 ULTRA Machine

The MX7 ULTRA machine range can manufacture large volumes of endmills and other cutting tools of the highest accuracy and quality. The machine’s performance can maintain less than +/- 0.00008 in. (+/- 0.002 mm) line form accuracy of any profile. It features a nanometer control system, servo control algorithm for smooth motion, and in-process measuring, balancing, and runout compensation for consistent accuracy. It also includes Motor Temperature Control.

To increase the stiffness of the C-axis, the MX7 ULTRA combines developments to the nanometer or micro degree resolution in the linear and rotary axis, tuning parameters, several system enhancements, and major mechanical changes.

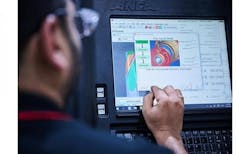

LaserUltra is part of the MX7 ULTRA package to maintain consistency and accuracy of the grinding process. Tool and wheel performance can be further optimized by the iBalance software, which guides a user to the optimal grinding position and rpm for vibration monitoring and balancing the wheelpack inside the machine. A major inclusion in the MX7 ULTRA package is the total tool runout measurement and compensation operation in iGrind.

- One nanometer resolution control system

- New servo control algorithm

- System and mechanical upgrades

- In-process measuring, balancing, and runout compensation

- Motor Temperature Control

- Specialist training support