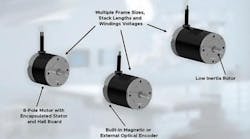

Portescap, a Danaher Motion company, introduces a stator-enhanced version of its h3 Series Step Motors. New h3 models feature patented enhancing magnets in the stator to provide 25+% more torque output across the entire speed range compared with original h3 models, which already deliver up to 40% more torque than traditional hybrid step motors. “The increased torque is achieved through additional stator magnets that are inserted between each stator tooth. These block the magnetic field from flowing around the stator teeth, which forces more of the magnetic field to flow through each tooth to produce the highest torque output of any hybrid step motor available today,” says Dave Beckstoffer, Portescap Product Specialist, Stepper Technologies. With its industry-leading efficiency and performance, the h3 allows machine builders to reduce the size and weight of their machine by utilizing a smaller motor to deliver the same performance of larger hybrid steppers. This further allows machine builders to use smaller drives, which reduces power requirements and overall system costs. Machine builders using the same size h3 as a standard hybrid will realize increased machine throughput. As a result, these RoHS-compliant hybrid step motors are an ideal solution in medical device, semiconductor equipment and laboratory instrumentation applications.These 1.8-degree step motors feature aluminum housing for superior heat dissipation, Neodymium iron boron magnets for optimized torque density, and a bearing retainer and o-ring to help reduce motor noise. Larger bearings enable the motor to effectively handle higher side and radial loads. They are available in NEMA 17, 23 and 34 frame sizes, with various stack lengths available in each frame size. Windings can be customized to suit individual application needs.