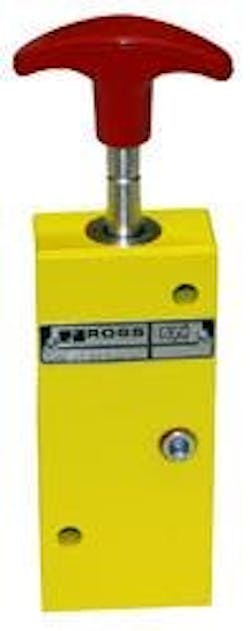

L-O-X® Valve Family

Ross Controls is adding to its family of OSHA-compliant L-O-X® (Lock Out & eXhaust) valves with two models that feature smaller port sizes (1/4” and 3/8”) for machines like those operating in the packaging industry and other industries. OSHA regulations (29 CFR 1910.147) and ANSI standards (Z244) require that energy sources (pneumatic, electric, hydraulic, etc.) be shut off or disconnected while equipment is being serviced. Furthermore, the disconnected valve or switch must be locked to prevent reactivation while anyone is servicing or performing maintenance on the equipment. The manual L-O-X® valve controls the airflow simply by moving its large red handle in or out. The valve is open when the handle is pulled outward and air then moves freely from inlet to outlet port. A short inward push of the handle shuts off airflow of air and opens the exhaust port to immediately release downstream air. Similarly the family of L-O-X® products assists manufacturers and users comply with European regulation EN 1037 (Safety of Machinery) and Canadian Standard CSA Z460 (Control of Hazardous Energy). Furthermore, some specific American and Canadian industry standards, such as ANSI/PMMI packaging equipment standards (B155, 1/7.11.1), CSA Power Press Operation (Z142), and pending ANSI B11 General Safety Regulations (B11 GSR) have four specific requirements for valves used for lockout. The valve must be easy to operate such as a simple push and pull, the valve must only be able to be locked in the off position that blocks the supply and exhausts downstream air, the valve must have a full-sized exhaust port to achieve air exhaustion in a timely manner, and finally there must be a way to verify that the downstream air has been removed. The ROSS L-O-X® valves meet all four requirements and includes an indicator port option for test point verification of absence of energy downstream of the L-O-X® valve next to the device in the pneumatic circuit. An additional feature unique to Ross includes using Teflon® seals to combat sticking rubber seals that can sometimes affect valves that are used infrequently. This provides a sure shifting force throughout the live of the valve. “The new L-O-X® valve has a balanced design,” explains Eric Cummings, a safety industry specialist at Ross Controls. “There is equal pressure on both sides of the spool so that an operator only has to overcome friction, not extreme air pressure to open and close the valve.”