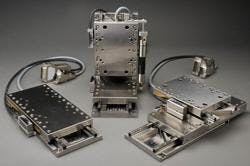

New Mini Mag Stages

Dover, A Danaher Motion Company, introduces the MMG Mini-Mag line of precision linear motor stages. Mini-Mag Stages deliver nearly twice the accuracy at virtually the same cost as competitive standard-grade options. Lead times of two weeks or less facilitate reduced-time-to-market with a higher performing machine for OEMs, or provide greater machine uptime for end users in production environments. The ability to deliver MMG prototypes rapidly speeds the proof-of-concept phase of an instrument under development.Four models are available that deliver 25mm, 50mm 100mm and 150mm travel, respectively. They provide uncompensated accuracy ranging from 2um to 8um and resolution ranging from 1.0um to 5nm. Each model delivers repeatability to ±0.4um and is rated for 8kg load capacity.One of the most significant features is an Integral anti-creep linear guideway, which can increase uptime by as much as 15% in high duty cycle applications by eliminating the need for homing moves typically required to reset standard crossed roller bearing retainer cages. These stages also feature adjustable limits to reduce the time needed to make adjustments to stage travel, thus reducing prototype development time and system startup costs by up to 10%. An integrated advanced feedback mechanism enables exceptional uncompensated accuracy. This encoder eliminates the need for compensation tables or slope correction factors, thus lowering software and integration complexity and implementation time. A standard “Z” axis counterbalance kit eliminates the typical engineering required to integrate a “Z” option, thus reducing the implementation time of a “Z” axis stage.MMG stages leverage a standard 3-phase brushless motor to enable control with various OTS drives and controllers, and deliver up to 20% greater throughout compared with piezo-driven actuators. No specialized piezo or proprietary motor/drive technology is necessary.The MMG stage can be used in constant velocity (CV) or high throughput point-to-point applications, allowing common units to be used. For OEMs, this lowers Bill-of-Material (BOM) costs while reducing and simplifying their unique parts count. Their precise performance, short lead times and lower cost of ownership make them ideally suited for use in life science and clinical diagnostic instruments. They are also well suited for use in OEM Metrology applications and photonics/laser machining applications.