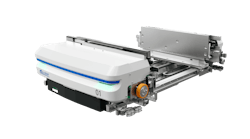

Schneider Packaging Equipment Company introduces the HVCP case packer, the ultimate in flexibility and rapid changeover for versatile case packing for cartoned products.Schneider Packaging has created an innovative case packer that can orient product either vertically, horizontally, or a combination of both, with the press of a button, using one case packing machine. The Schneider HVCP is perfect for packaging operations that have multiple products and multiple pack orientations that in the past would have required manual packaging or multiple machines or complex changeovers. “This innovative solution is ideal for customers with multiple SKUs or short production runs,” says Terry Zarnowski, sales and marketing director for Schneider. “The HVCP provides our customers with the flexibility and speed to adapt to their ever changing production needs with very high operating efficiency and lower manufacturing costs.”Product is collated into the proper pack pattern by a Fanuc robot, a second Fanuc robot picks and places the collated product into an erected case. After loading, the carton indexes through the flap folding and sealing stations and is sealed. The fully sealed and completed case is discharged from the machine onto the customer’s takeaway conveyor. Simultaneous operations including case erecting, accumulation, case loading and case sealing are ongoing during operation.The HVCP integrates design features that enhance operational efficiency and throughput; Positive case erection improves system tolerance to case variations; Open design allows easy access for rapid jam recovery and simplifies maintenance; Flexible tooling and smart software minimize product changeover downtime; Robotic accumulation replaces traditional complex mechanical accumulation methods further improving efficiency and longevity. This built-in versatility accommodates changing production requirements and has the flexibility to meet future needs.The machine’s small footprint reduces floor space requirements while retaining all the rugged durability that is the hallmark of Schneider equipment. The Schneider HVCP offers a user-friendly set-up utilizing FANUC robotic arms with optimized Human Machine Interface that simplifies changeover and eliminates programming. A standard ethernet port allows remote monitoring and diagnosis. The HVCP can be designed to pack virtually any product, including rigid cases, bags, cartons, or trayed products at high speeds. • Case Type: op load Regular Slotted Case (RSC) or Half Slotted Case (HSC) • Sealing: Tape heads or hot melt glue • Main Drive: Intermittent motion driven index • Construction: Stainless steel or painted carbon steel • Controller: PLC microprocessor • Case Magazine: 48” standard (40” of storage capacity - board thickness determines capacity) - 2’ increment extensions available up to 10’ • Guarding: Meets ANSI/PMMI B155.1 safety standards • Enclosures & Electrics: NEMA 4, 4X, or 12 electrical with lockout, tagout disconnect • Power: 230/380/460 or 575 volt, 3 phase 50/60 hertz plant power, Air requirement delivered at 90 psi - 3/4 NPT • Visual Display: Touchscreens – color or grayscale