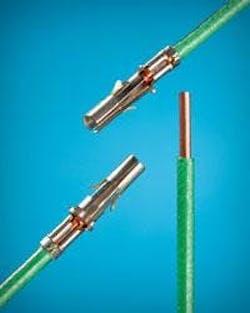

CRIMP ON SOLID WIRE ELIMINATES SOLDERING AND WELDING

Nov. 18, 2009

Related To:

A new crimp ear design for electrical terminals that exceeds UL 310 spec-ifications and can be crimped on stranded and solid wire using high speed applicators is being introduced by ETCO Incorporated of Warwick, RI.ETCO’s Crimp Ear Design creates reliable terminal connections on both solid and stranded wire and meets or exceeds UL 310 specifications, depending upon the application. Eliminating the need for soldering and welding processes, terminals featuring this open-barrel crimp ear can be made from a wide range of clad and inlaid alloys in configurations from .008” to 0.900” thick with tolerances to ±0.002”, depending upon the materials and specific design.Supplied as continuous strip on reels and supported by the firm’s high-speed application equipment, ETCO’s Crimp Ear Design is available in brass, tinned brass, nickel-plated steel, copper plated steel, tinned steel bearing bronze, phosphor-bronze, beryllium-copper, and high temperature alloys. Custom OEM terminal development from concept to manufacture is offered.ETCO Terminals for crimp on solid and stranded wire are priced according to configuration and quantity. Samples and price quotations are available upon request.