Case Study: Discovering the Right Support for Lost Reusable Shippers

PROBLEM

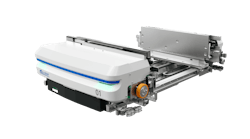

One of the largest pharmaceutical manufacturing companies in the world was sending reusable Cr?do™ parcel shippers to Australia, Singapore, and other parts of SE Asia, but found returning the containers individually wasn’t cost effective for them. They had other temperature controlled products available, but they wanted to use the Cr?do shipper due to their familiarity with the reliability, value in the Total Cost of Ownership (TCO), and temperature hold capabilities experienced in other regions with more established shipping lanes like Europe and North America. Nonetheless, shipments to Asia had to be made, so this company accepted the one-way shipments as status quo because the thermal performance of the reusable Cr?do shippers was worth it to them. Without a way to organize or track asset management, this company was losing as much as $200K in irretrievable shippers each year and this was an acceptable, if expensive situation for them.

SOLUTION

One of the pharmaceutical company’s vendors in the region was familiar with the reusable nature of Cr?do, so they saved the systems. Once they had several pallets worth stored in their premium warehouse in Singapore, they contacted the local headquarters for the pharmaceutical company to determine how they wanted to return them. The logistics manager reached out to PBT citing irretraceable shippers was surprised to hear about the pallets of reusable Cr?do shippers just waiting to be reclaimed and found himself unsure how to track them for reuse when they had been sent to Asia on a one-way trip. At this point, the logistics manager contacted Pelican BioThermal for advice and assistance.

Pelican BioThermal introduced our asset management software, Cr?do ProEnvision™. With this software implemented, our client was able to have full visibility into their inventory. They established a consolidation facility with their local vendor for all countries in the region to which they sent Cr?do shippers. They used scans from the shippers in each country and Cr?do ProEnvision™ to track where each shipper landed in Asia, then determined where each had been shipped from originally. Once they had a way to track their adrift Cr?do shippers, their vendor sent them from each Asian country and Australia to the consolidation facility in Singapore. Through Cr?do ProEnvision™, the pharmaceutical company and their vendor monitored the returns coming to the consolidation facility and the rate at which the containers were returning to them. As a result, the collected pallets of Cr?do shippers were scanned upon arrival and tracked in Cr?do ProEnvision™. From that point on, Cr?do shippers sent to Asia were monitored, reclaimed at the consolidation facility, and put right back into service, which, aside from excellent thermal protection, reuse is a primary strength of the Cr?do shippers.

OUTCOME

1,200+ Cr?do shippers were returned to date for this client and they have saved over $120,000USD in the first year of problem discovery thanks to Cr?do ProEnvision™. The company estimate their savings to total $200,000USD annually in year two and beyond. The client is very pleased to have such significant savings in reusing the Cr?do shippers just waiting to be found by the very supportive tool for asset management: Cr?do ProEnvision™.