PowerCycling PCX Elongated Thermoelectric Coolers

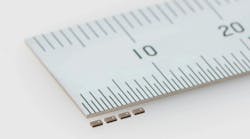

Thermal Cycling devices used for Real-Time PCR use thermoelectric technology to precisely manage temperature set points and ramp rates, enabling the amplification of DNA segments. To improve temperature precision control in PCR devices, Laird has developed an elongated series of PowerCycling PCX thermoelectric coolers. The series provides high reliability and a minimal temperature gradient for PCR applications resulting in greater throughput and faster test results.

PCR requires a high number of thermal cycles to create millions of DNA strands used for medical diagnosis. Each thermal cycle consists of three steps, where the first separates the DNA strands at a high temperature of 203°F (95°C). The second step is a cool down to a melt temperature between 122 to 149°F (50 to 650°C) where the biomarkers will bond to the DNA and the third stage increases the temperature to 161.6°F (72°C) to sequence a copy of the DNA. Thermoelectric coolers are installed under the PCR wells to precisely manage these temperature setpoints to within ±1°F (±0.5°C).

Determining the optimum melt temperature of each thermal cycling stage is often a time-consuming process for laboratory technicians. By creating more temperature zones on the PCR tray, the optimal melt temp can be found. The series allows for more narrow temperature zones than standard thermoelectric coolers, providing more precise temperature control across the tray, making it easier for technicians to determine the right temperature.

It's constructed with a thermally conductive “soft layer” that absorbs the mechanically induced stresses caused by thermal cycling applications and is tested to meet the latest PCR industry standards without degrading in performance.

- High thermal cycling capability

- Precise temperature control

- Solid-state operation

- Boosted performance with next-gen material

- RoHS-compliant