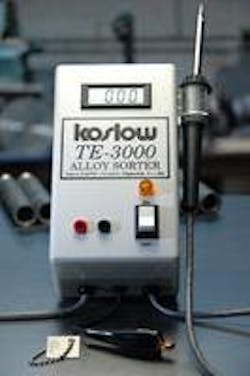

Thermoelectric Alloy Sorter

Koslow Scientific Company provides quality engineers, manufacturers and fabricators with a fast and simple metal testing device called the Thermoelectric Alloy Sorter or the TE-3000. This Thermoelectric Sorter is used to inspect critical piping, flanges, tanks, bearings, finished parts and much more.

The Thermoelectric Alloy Sorter can be used for rapid field identification of materials such as steels, nickel, aluminum, titanium alloys, stainless steels, super alloys, specialty steels, tool steels, low alloy steels, and common steels. Other applications include the detection of platings and plasma coatings, in-line and part testing, and scrap sorting.

The Thermoelectric Alloy Sorter is the fastest metal sorter available, taking only one second per test. Thermoelectric technology is as simple to understand as an ordinary thermocouple and is widely accepted because it’s an ASTM approved method for sorting (ASTM E977). The easy-to-use sorter eliminates the need for costly labs and slow turnaround times. The thermoelectric method of sorting is also extremely safe as no harmful isotopes or X-rays are used. Operating the TE-3000 is simple and requires little training.

Top fabricators in many industries worldwide, including scrap recyclers, pharmaceutical OEM and aerospace industries, have chosen KSC’s Thermoelectric Alloy Sorter. The TE-3000 has also been used with Programmable Logic Controls and other automated quality inspection environments.

The updated TE-3000 now includes:

- Specialized interchangeable probe tips for improved test metal contact

- Handy protective carrying case

- International voltage regulator

- Data logging

- Specialized interchangeable probe tips for improved test metal contact

- Handy protective carrying case

- International voltage regulator