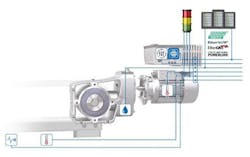

NORD’s Condition Monitoring solution helps maintain machines and plants proactively as a preventative measure to reduce downtimes and increase overall efficiency. It provides real or near-real-time drive and status data which is recorded periodically or continuously to optimize operational safety. This data is stored on a local industrial PC where you can have the drive information transferred and summarized on a remote dashboard.

- Detection and avoidance of impermissible operating states at an early stage

- Status-oriented maintenance replaces time-based maintenance

- Plannable machinery and plant downtimes based on real drive and process data

- Reduction of service and material costs

- Longer service life of components and machine

- Increase in system availability

- Avoidance of unplanned downtimes

- Plannable and cost-optimized repair