ProJet MJP 5600 Multi-Material 3D Printer

June 7, 2017

Related To:

ProJet MJP 5600 offers print speeds up to two times faster, a larger build volume, and part costs that are up to 40% less than competing multi-material 3D printers.

Featuring best-in-class jetting technology, the system's multi-material capabilities enable customers to digitally blend rigid and elastomeric materials at the voxel level to achieve superior mechanical properties for a wide range of applications, including assemblies, rubber-like components, jigs and fixtures, and dies.

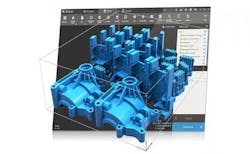

Coupled with 3D Sprint software, the ProJet MJP 5600 also allows customers to assign different material blends to separate shells within a single part.

- MultiJet Printing technology

- Max build envelope capacity (W x D x H): 20.4 x 15 x 11.8 in (518 x 381 x 300 mm)

- 5 base materials: rigid white, black, clear, elastomeric black or natural

- More than 100 composite combinations

- Streamlined design-to-print workflow with 3D Sprint software capabilities

Applications:

- Design testing and verification, including snap-fit and prototype part count reduction

- Water-tightness applications, fluid flow or internal structures visualization

- Functional testing of plastic and elastomeric products

- Rapid tooling

- Jigs and fixtures

- Master patterns for RTV molding

Benefits:

- Get more parts faster with high throughput from file to finished part

- High fidelity parts you can rely on

- Exceptional sharp edges and fine features definition

- Greater geometric freedom with effective supports removal

- Use high-performance multi-materials composites capability for a wide range of applications

- Low Total Cost of Ownership (TCO)