Infrared Camera for High-Voltage Equipment Monitoring

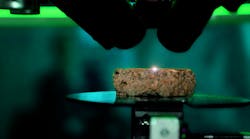

ThermalSpection 724 substation asset monitoring system includes a hardened enclosure with thermal and visual imagers mounted on a pan-tilt positioner. An essential part of the upgraded system includes new interfaces to easily automate data collection and analysis. Hardware updates include a higher resolution infrared camera with a powerful lens.

The new design incorporates a 640 x 480 pixel infrared camera with a telephoto lens. These work together enabling the system to detect problems sooner and at a greater distance. Included in the system is a stainless steel junction box and connection cables enabling quick field installation. LumaSense also offers a field hardened controller or users can deploy the control software on their own systems. LumaSpec RT software that is included allows users to define automated “inspection tours” of the substation or industrial setting. The system can be expanded with optional fixed thermal imagers and fixed single point infrared pyrometers for monitoring assets not within the view of the ThermalSpection 724 pan-tilt (TS724DV-PT) camera.

Two primary paths for data analysis are supported. One is to publish the measurements to the user’s data historian using standard protocols. The second is new software called LumaTrend that archives the measured data and images in a Microsoft SQL database. LumaTrend analyzes that data over time using built-in industry standard analytics to help provide early detection of problems and can use the images to create time-elapsed video (both infrared and visual) of the equipment monitored. This software can help identify transient thermal events not detectable with manual inspections. Along with authenticated web browser access, users can receive email notifications for reports, alarms, and warnings.

Temperature Range | -40...500 °C |

Measurement Accuracy | ±2 °C or ±2% (whichever is greater) |

Resolution | 640 x 480 pixels |

Field of View | 8.2° x 6.2° (75 mm lens) |

Infrared Imager | 640 x 480 resolution uncooled microbolometer detector |

Image Update Rate | Variable depending on operational mode (tour, alarm) |

Emissivity Correction | 0.1...1.0 |

Background Compensation | Provided |

Lens focal Length | 75 mm |

Focus | Autofocus |

Ambient Temperature | -40...60 °C with optional enclosure heater |

Storage Temperature | -40...75 °C |

Weight | 26 kg (57 lbs) |

Communication | Gigabit Ethernet |