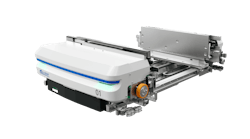

Vertical Lift Module - SSI Schaefer Systems International, Inc.

LogiMat® vertical lift module (VLM), manufactured by SSI SCHAEFER is a simple goods-to-person concept. Incoming goods are put into the high-density, automated, carousel storage VLM. As orders for parts, or for shipping are required to be filled, the items are automatically retrieved from the storage system and brought to the picker at an ergonomic receipt station, where items are then picked from partitioned drawers. Since the picker does not have to walk, the focus at the pick station is on ergonomics and high productivity.

Most Versatile Vertical Lift Module

LogiMat is the most advanced and versatile VLM available, providing a suite of capabilities that deliver a six- to ten-fold increase in order picking speeds, reduced picking errors, and a compact footprint. Its unique features include…

Rack & Pinion Drive: Used for movement of the elevator and extractor, rack and pinion provides a more positive movement, better tray stability and less servicing compared to chain- and belt-driven designs.

Ergonomics: The opening height adjusts to the worker to ensure an ergonomically correct operating height, while a tilt mechanism allows for a reduction of reach depth, facilitating the ergonomic removal of goods.

Laser Pointer: The LogiPointer® laser pointer system, assisted by a centrally located touchscreen, identifies the location in the drawer of the part to be picked, making the picking of orders clear and easy.

Security: An electrically-driven locking door provides security for storing valuable goods. Light barriers can be employed to protect the operating opening. Restricted accesses are possible with password protected login. All system events and errors are logged and can be viewed for maintenance.

Scalable Controls Software: From a basic controls design enabling storage and retrieval of the trays by identification numbers, to a full inventory control solution supporting multiple zones. Capable of support shelves, pallets, goods reception, consolidation and shipments.

Optimized Tray Positioningand Batch Order Picking: The smart placement algorithm finds the optimal position for each tray, and always finds the most streamlined picking sequence to optimize the pick process.

Flexible Tray & Compartment Options: Variable tray dimensions (length, width and height), and weight capacities from 550 to 1,980 lbs. Virtually limitless choice of compartment accessories available from SSI SCHAEFER’S extensive plastic container portfolio.