Due to the increasing quality expectations and standards of retailers, manufacturers are frequently looking for simple solutions to help safeguard the quality of their products. Responding to those needs, Videojet Technologies Inc., a global leader in coding, marking and printing solutions, has introduced the new Videojet Code Detection System, a combination of hardware and software that provides an enhanced level of Code Assurance by automatically checking for the presence of a printed code on every product. Videojet surveyed a variety of consumer goods manufacturers with fast-moving production lines and found that all had experienced coding errors – many of them on a frequent basis. The survey showed that nearly half the companies responding were having trouble with coding errors at least once per week, with one-quarter reporting coding errors at least once per day. Solutions that identify errors before products are put into the supply chain can help save time, money and rework. Ideal for flat packaging with a white or light marking window, the new Code Detection System allows manufacturers to easily inspect ink jet printed codes on their packaging. Using presence/absence detection, the system verifies that the amount of contrast in the marking area is sufficient, helping to catch common printing issues including missing, mis-positioned and clipped codes.

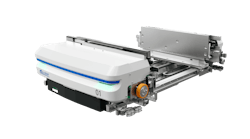

“Many customers implement standard procedures to manually check printed codes periodically during a production run. Automatic code detection provides an additional level of coding confidence by inspecting every code, and can therefore deliver an earlier alert than would typically be provided using manual inspection processes,” said Anthony Blencowe, business unit director for Videojet. The Code Detection System allows users to easily set a threshold for a code to be considered unacceptable, as well as set a limit for the number of bad codes that can be detected before a fault is indicated. When the specified quantity of bad codes is detected, the system can automatically send an alert signal to eject product or stop the production line, allowing operators to take corrective actions. “The system can help reduce scrap and rework since it aids in alerting users of code defects at the time of production, enabling issues to be resolved immediately,” added Blencowe. “Users can quickly identify the root cause of the printing error by reviewing the bad code images stored on the system controller and take action to prevent reoccurrence.” The system bracket holds the product detector, printhead, camera and print detector automatically in alignment with each other, providing optimum performance without the need for physical adjustments.

Integrated lighting takes the guesswork out of system configuration, removing the need for manual alterations and helping to eliminate errors associated with changes in ambient light. Sophisticated camera-based verification systems have been used on packaging lines for years, but they often deliver more technical capabilities than most packaging lines need and may require special training for set-up and use. The Videojet Code Detection System offers a simple 3-step set-up process that simplifies training and minimizes changeover time. Blencowe added, “Videojet has been successfully integrating advanced vision systems from leading machine vision companies for over two decades. We have taken that experience and developed a simple yet powerful tool that provides customers with an easy way to strengthen their existing quality control processes.”